When working with wood, safety should be your top priority. Wearing the right safety gear can protect you from various hazards like flying wood chips, dust, and accidental cuts. Always wear safety glasses or goggles to shield your eyes. Wood dust can irritate your eyes and lead to long-term vision problems, so this simple step is crucial.

In addition to eye protection, use hearing protection such as earplugs or earmuffs. Power tools generate high noise levels that could damage your hearing over time. Dust masks or respirators help prevent inhalation of harmful wood dust, which can affect your lungs.

Don’t forget to wear appropriate clothing. Avoid loose sleeves or jewelry that could catch on machinery. Wearing sturdy, closed-toe shoes protects your feet from dropped tools or nails. Gloves might be useful, but be cautious when operating machines, as gloves can sometimes get caught, increasing the risk of injury.

Safe Handling and Operation of Woodworking Tools

One of the most essential practices in woodworking is knowing your tools well. Whether you’re using saws, drills, or sanders, always read the manufacturer’s instructions before starting. Check all equipment for damage or wear before use. Faulty tools can lead to accidents and poor workmanship.

Maintain sharp blades and bits. Dull tools can slip or require excessive force, increasing the chance of injury. Replace or sharpen blades as needed to ensure clean cuts.

When operating power tools, always use guards and safety features. Never remove or bypass them. For example, blade guards and anti-kickback devices on saws are designed to keep your hands safe and prevent kickback injuries.

Keep your hands away from moving parts and cutting edges. Use push sticks or push blocks when feeding wood into saws to keep your hands safe.

How to Set Up a Safe Workspace

Your workspace plays a significant role in maintaining safety. Keep your area clean and free from clutter to avoid tripping hazards. Good lighting is essential—working in a dim area can lead to mistakes and accidents.

Arrange tools and materials so they are within easy reach but not overcrowded. Cords should be neatly organized and out of walking paths to prevent tripping.

If possible, install dust extraction systems or use portable dust collectors. These help keep your workspace clean and reduce airborne wood dust, protecting your respiratory health.

Ensure all electrical outlets and tools are properly grounded. Faulty wiring or power surges can cause shocks or fires.

Critical Practices to Follow While Woodworking

- Stay Focused: Avoid distractions. Pay close attention when operating tools. Keeping your mind on the task helps prevent accidents.

- Use Proper Techniques: Don’t force tools. Let the blade or bit do the work at its own pace. This reduces strain and lessens the chance of slips.

- Keep Both Hands on Tools: Maintain a firm grip and balanced stance. This control is vital for precise and safe cuts.

- Disconnect Power: Always unplug tools before changing blades, bits, or performing maintenance.

- Follow Manufacturer Safety Instructions: They provide tested methods to use tools safely and effectively.

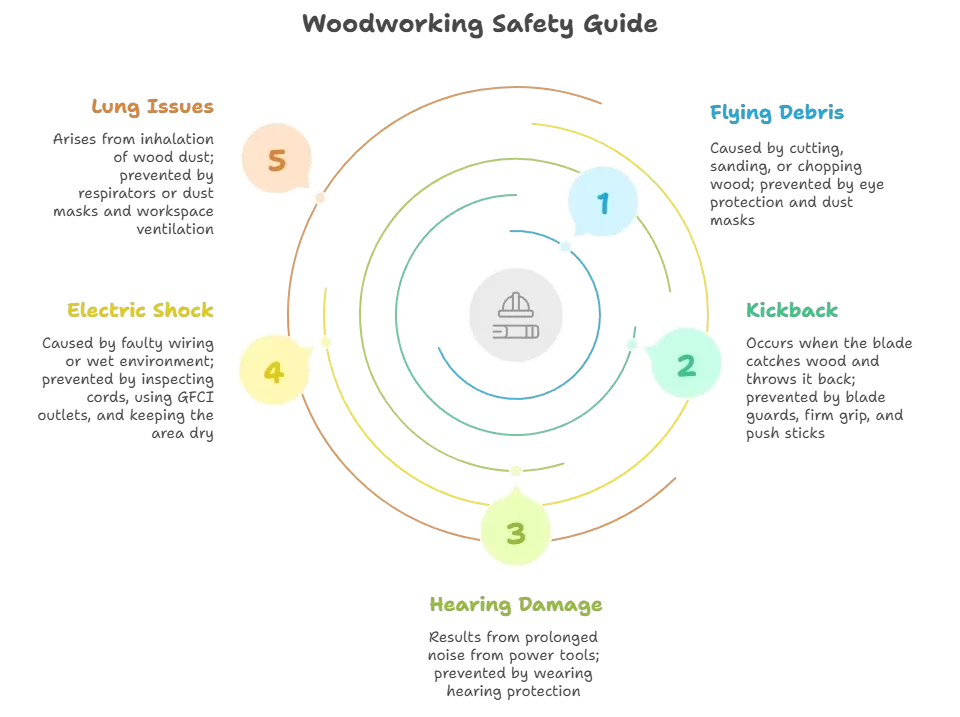

Common Woodworking Hazards and How to Avoid Them

| Hazard | Cause | Prevention |

|---|---|---|

| Flying Debris | Cutting, sanding, or chopping wood | Wear eye protection; use dust masks |

| Kickback | Blade catches wood and throws it back | Use blade guards, hold wood firmly, use push sticks |

| Hearing Damage | Prolonged noise from power tools | Wear hearing protection |

| Electric Shock | Faulty wiring or wet environment | Inspect cords, use GFCI outlets, keep area dry |

| Lung Issues | Inhalation of wood dust | Use respirators or dust masks; ventilate workspace |

Additional Tips for Woodworking Safety

Keep a first aid kit handy in your workspace to handle minor injuries quickly. Knowing basic first aid boosts your confidence and can minimize complications from accidents.

Don’t work when you’re tired or under the influence of alcohol or drugs. Fatigue and impaired judgment increase the risk of mistakes and injuries. Take breaks to rest your muscles and eyes during long sessions.

Consider taking a woodworking safety course, especially if you’re new to the craft. These courses provide hands-on experience and teach you how to work confidently with tools.

For more detailed guidelines and safety resources, you can visit Woodworking Safety 101 or browse safety standards at OSHA Woodworking Safety.

Choosing the Right Personal Protective Equipment for Woodworking

Essential Gear for Protecting Your Eyes

When working with wood, the tiniest chips or dust particles can fly up and cause serious eye injuries. Choosing the right eye protection is crucial for your safety. Look for safety goggles or impact-resistant glasses that fully cover your eyes and fit comfortably. Glasses with side shields provide extra protection from debris coming from different angles.

For those using power tools like saws, planers, or routers, goggles with anti-fog coating are ideal. They ensure you maintain clear vision without constantly stopping to wipe off moisture or dust. If you wear prescription glasses, consider goggles that fit over them or specialized safety glasses with your prescription.

Protective Respiratory Gear to Keep Your Lungs Safe

Wood dust contains particles that can irritate your lungs or cause long-term respiratory problems. Wearing the right mask or respirator helps you avoid inhaling these harmful materials.

- Dust masks: For light wood dust exposure, disposable dust masks rated N95 are a good choice. They filter out most airborne particles but are not suitable for chemical vapors.

- Respirators: When working with finishes, stains, or solvents, use a respirator with cartridges designed to filter both dust and fumes. Half-face respirators provide better protection in these scenarios.

Make sure your mask fits snugly to prevent air leaks. Facial hair can reduce the effectiveness of respirators, so consider shaving if you are using these frequently.

Choosing the Right Hearing Protection

Woodworking tools can produce noise levels that may damage your hearing over time. Consistent exposure without ear protection can lead to permanent hearing loss. To stay safe:

- Earplugs: These are small, inexpensive, and easy to wear. They block harmful noise but allow you to hear important sounds around you.

- Earmuffs: Provide a higher level of noise reduction and are comfortable for extended wear. Some advanced models feature electronic sound control to filter noise selectively.

It may be worth trying both options to see which fits more comfortably during long woodworking sessions.

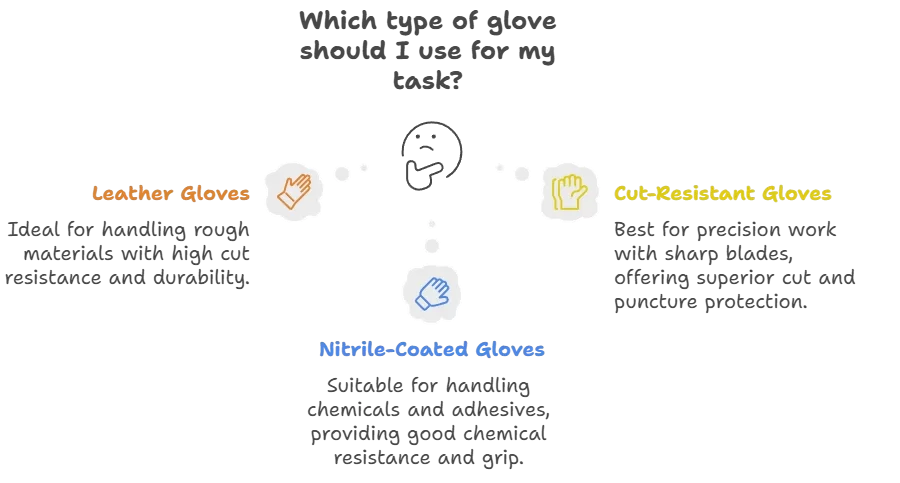

Hand and Arm Safety Equipment

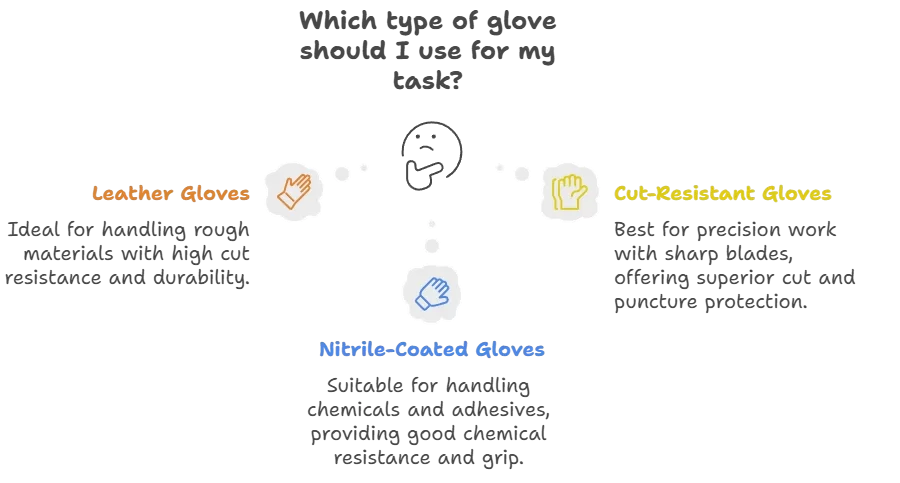

Your hands are your most valuable tools in woodworking, which means protecting them is vital. Different tasks call for different types of gloves designed to provide a balance of protection and dexterity.

| Glove Type | Best For | Protection Level |

|---|---|---|

| Leather gloves | Handling rough wood, splinters, and sharp edges | High cut resistance and durability |

| Cut-resistant gloves (Kevlar or similar) | Using sharp blades and precision work | Superior cut and puncture protection |

| Nitrile-coated gloves | Handling finishes, stains, or adhesives | Good chemical resistance and grip |

Always avoid loose gloves near rotating tools to prevent entanglement injuries. For fine carving or sanding, using gloves may reduce your grip and precision, so be mindful of the task requirements.

Footwear and Clothing for a Safe Workshop

Protective footwear is often overlooked but essential when working around heavy wood pieces and sharp tools. Steel-toe boots or shoes provide critical protection against dropped objects and punctures.

Wear clothing that fits well without loose sleeves or dangling parts. Loose clothing can catch in machinery, posing a serious safety risk. Durable, long-sleeved shirts and pants made from natural fibers help shield your limbs from minor cuts and abrasions.

Additional Safety Accessories

Other useful items that help enhance your safety while woodworking include:

- Face shields: For heavy-duty work or when grinding, a full-face shield protects your face from flying debris.

- Aprons: Heavy-duty canvas or leather aprons guard against splinters and spills.

- First aid kit: Keep a kit nearby with supplies for cuts, splinters, and eye rinsing solutions.

Before starting any woodworking project, it’s best to review your personal protective equipment to make sure it’s suitable and in good condition. When in doubt, refer to trusted resources like the OSHA woodworking safety guidelines for detailed recommendations on the proper PPE.

Choosing the right personal protective equipment creates a safer work environment, reduces accidents, and ensures you enjoy woodworking with confidence and peace of mind. Remember, investing time in selecting and properly using protective gear is just as important as your skills and tools.

Safe Handling and Maintenance of Woodworking Tools

Essential Practices for Handling Woodworking Tools Safely

Working with woodworking tools can be rewarding, but safety should always come first. Proper handling of equipment like saws, chisels, and planes prevents accidents and ensures the quality of your craft. When you handle woodworking tools, always keep your focus sharp and your hands steady. Avoid distractions, and never operate tools if you feel tired or unwell.

Here are key points to remember when using woodworking tools safely:

- Wear Personal Protective Equipment (PPE): Always use safety glasses to protect your eyes from flying debris, hearing protection when using loud power tools, and gloves if recommended for the task.

- Maintain a Clean Workspace: Keep your workbench free from clutter. Tools and materials scattered around can cause trips or slips.

- Check Tools Before Use: Inspect blades, cords, and handles for damage or wear. Dull blades increase the risk of accidents, so sharpen or replace them as needed.

- Use Tools for Their Intended Purpose: Do not use a chisel as a screwdriver or an inappropriate saw blade on the wrong material.

- Secure Wood Properly: Clamp your workpiece firmly to prevent movement during cutting, sanding, or shaping.

Routine Maintenance to Keep Tools in Optimal Condition

Good maintenance of woodworking tools is vital for your safety and the tools’ longevity. Neglecting maintenance can lead to tool failure and poor-quality work. Create a regular schedule to clean, sharpen, and store tools properly.

Cleaning and Lubricating

After each use, clean tools with a dry cloth to remove sawdust and resin build-up. You can use a soft brush or compressed air for intricate parts. Apply a thin layer of lubricant or oil (such as camellia oil or machine oil) to metal components to prevent rust. Avoid excessive oiling, which can attract dust.

Sharpening Blades and Cutting Edges

Sharp blades not only improve precision but also reduce the effort required, lowering the chance of slips or mistakes. Use a sharpening stone, honing guide, or an electric sharpener, following the manufacturer’s guidelines. Remember that dull blades can “grab” wood unexpectedly, risking injury.

Electrical Tool Care

For power tools, inspect the electrical cords regularly for cuts or frays. Replace damaged cords immediately to avoid electrical hazards. Ensure that moving parts like belts and motors are cleaned and lubricated according to the tool’s manual. Never operate tools with grounding issues or exposed wires.

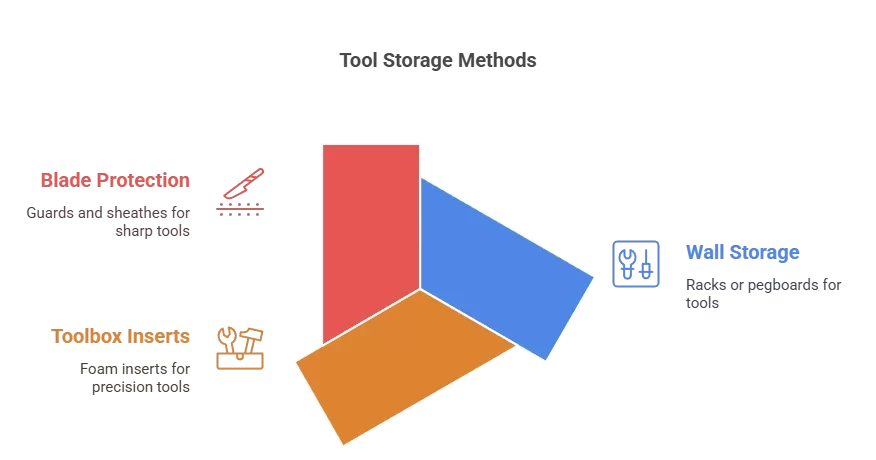

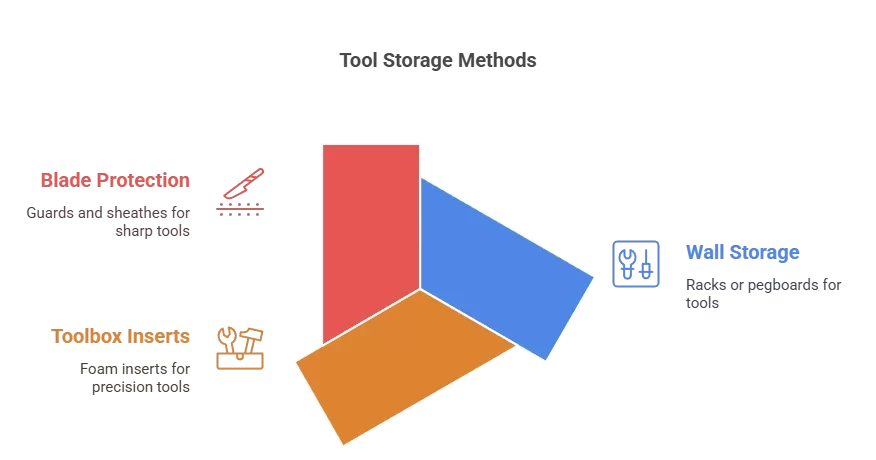

Proper Storage Techniques to Enhance Safety

Proper storage not only protects your tools but also helps prevent accidents caused by misplaced sharp objects.

| Storage Method | Tools Suitable | Benefits |

|---|---|---|

| Wall-mounted racks or pegboards | Hand tools like chisels, hammers, screwdrivers | Easy access, visibility, keeps tools off work surfaces |

| Toolboxes with foam inserts | Precision tools, small power tools | Protects delicate parts and prevents shifting |

| Blade guards and sheathes | Saws, planes, knives | Prevents accidental cuts and blade damage |

If you lack adequate space, consider portable cases with cushioning to transport tools safely between locations.

Ergonomics and Safe Posture to Reduce Risks

Handling tools effectively also depends on your posture and the ergonomics of your workspace. Position yourself so that you have a stable footing and easy reach of tools and materials. Avoid awkward angles that strain your wrists, arms, or back. Adjustable workbenches and anti-fatigue mats help reduce fatigue during long woodworking sessions.

Learning and Continuous Improvement

Educating yourself about tool safety and maintenance is an ongoing process. Many woodworking communities and websites provide free tutorials and safety checklists.

For trusted and detailed guidance, visit the Occupational Safety and Health Administration (OSHA) woodworking safety page. It covers industry-standard practices and tips.

You can also explore the Popular Woodworking safety resources, which offer expert advice on handling and maintaining woodworking tools with care.

Key Safety Reminders

- Never rush your work—patience reduces accidents.

- Disconnect power tools from electricity before adjusting or cleaning.

- Store tools in places inaccessible to children or untrained individuals.

- Use push sticks or feather boards when guiding small wood pieces near blades.

- Stay hydrated and take breaks to maintain focus and alertness.

Remember that investing time in the safe handling and maintenance of your woodworking tools is an investment in your well-being and the quality of your craftsmanship. Keeping these practices top of mind makes your woodworking both safer and more enjoyable.

Creating a Hazard-Free Workspace for Woodworking Projects

Essential Steps to Establish a Safe Woodworking Environment

When you set up your woodworking area, safety should be the foundation of every decision. A hazard-free workspace not only protects you but also boosts your productivity by minimizing interruptions caused by accidents. Here’s how to create an environment where you can work confidently and safely on your woodworking projects.

Choose the Right Location and Layout

Start by selecting a dedicated space with plenty of room to move freely around your tools and materials. Crowded areas increase the risk of trips and accidental contact with sharp equipment. Organize your workspace so that each tool has a clear, accessible place. Keep frequently used items within easy reach while storing other supplies safely away to avoid clutter.

Ensure Proper Lighting and Ventilation

Good lighting helps you see clearly and reduces mistakes that could cause injury. Position bright, shadow-free lights over your worktables and cutting areas. Avoid dim corners where visibility may be poor.

Woodworking creates fine dust and fumes from finishes and adhesives. To protect your lungs and maintain air quality, make sure your workspace is well ventilated. Use exhaust fans, open windows, or air filtration systems designed for workshop environments to keep the air clean.

Set Up a Tool Safety Zone

Power tools and hand tools are essential but can be dangerous if mishandled. Design a dedicated tool zone with safety in mind:

- Use sturdy workbenches with clamps to secure pieces and prevent shifts during cutting or sanding.

- Install guards on machines like table saws and jointers to reduce accidental contact with blades.

- Keep sharp tools like chisels and knives sheathed or in designated holders when not in use.

Maintain a Clean and Organized Workspace

Dust and wood scraps can clutter your area, creating slipping hazards or fire risks. Develop a routine to sweep floors and work surfaces regularly. Use a dust collector or shop vacuum to remove fine particles immediately after sanding or cutting. In addition, keep all chemical adhesives, stains, and finishes in clearly labeled containers, stored safely away from heat sources and out of reach of children or pets.

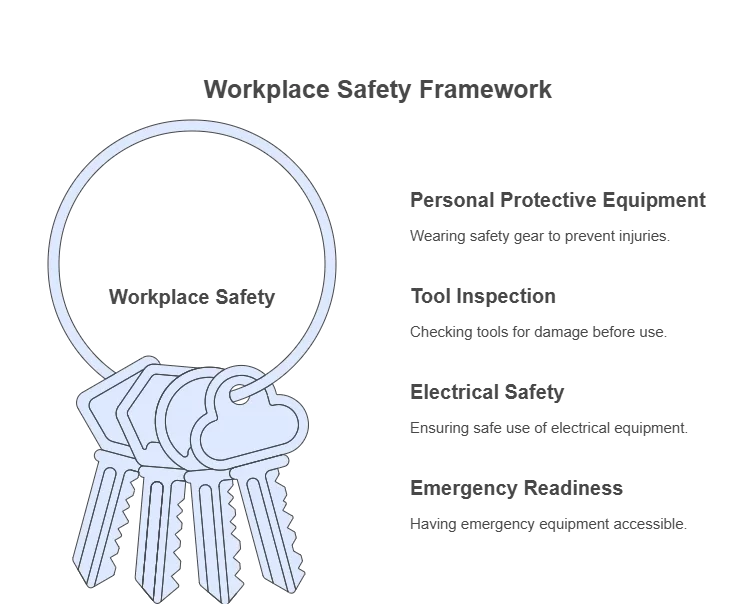

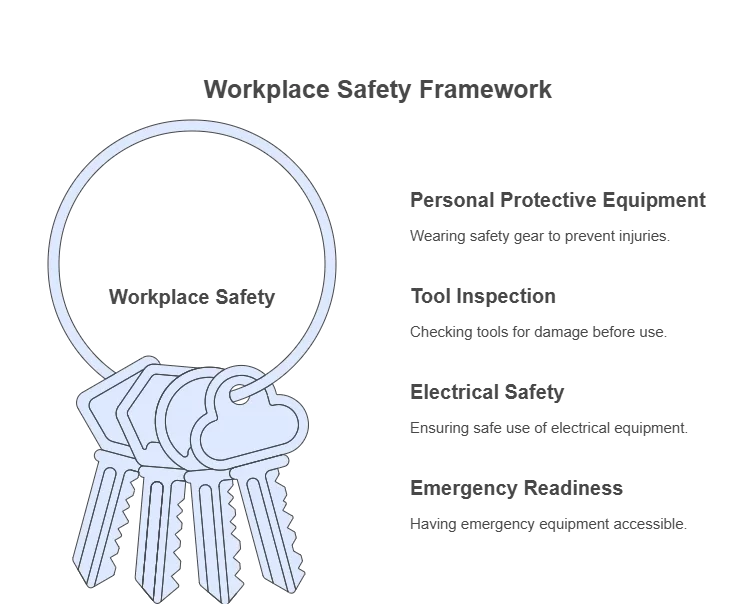

Establish Clear Safety Protocols

Having rules and procedures reduces guesswork and increases consistency in safe practices. Some helpful protocols to implement include:

| Safety Practice | Description | Benefits |

|---|---|---|

| Personal Protective Equipment (PPE) | Always wear safety goggles, hearing protection, dust masks, and gloves. | Prevents injuries to eyes, ears, skin, and respiratory system. |

| Tool Inspection | Check all tools before use for damage or wear. | Detects potential malfunctions early, preventing accidents. |

| Electrical Safety | Ensure cords are intact and outlets aren’t overloaded. | Reduces risk of electrical shocks and fires. |

| Emergency Readiness | Have a first-aid kit and fire extinguisher readily accessible. | Allows quick response to accidents or fires. |

Use Signage and Labels for Awareness

Visual reminders can reinforce safe behavior. Use clear, easy-to-read signs near hazardous areas or equipment to highlight risks. Label drawers, shelves, and containers so you and anyone else working in the shop know where everything belongs. This practice limits time spent searching for tools and lowers the chance of misplaced objects causing accidents.

Take Advantage of Quality Storage Solutions

Investing in proper storage systems helps maintain an orderly workspace. Consider the following options:

- Wall-mounted racks for clamps and hand tools.

- Lockable cabinets for chemicals and sharp accessories.

- Mobile carts to move tools safely between workstations.

Regular Maintenance and Inspections

Prevent hazards by scheduling routine checks on your workshop setup. Sharpen blades, lubricate moving parts, and replace worn-out safety features before problems arise. Keeping everything in top condition improves efficiency and cuts down on unexpected downtime caused by tool failure or accidents.

Learn More About Woodworking Safety

Expanding your knowledge can empower you to make safer choices. Trusted resources like the American Woodworking Association offer guidelines, courses, and updates on best safety practices. Additionally, the Occupational Safety and Health Administration (OSHA) provides detailed regulations and tips specifically for woodworking environments.

Creating a Hazard-Free Workspace Requires Planning, Commitment, and Ongoing Effort

By following these tips, you can protect yourself and enjoy your woodworking projects with confidence and peace of mind.

Emergency Procedures and First Aid in Woodworking Accidents

Recognizing Common Woodworking Injuries

Woodworking is a rewarding craft but carries inherent risks that require immediate and effective action when accidents happen. Knowing what type of injuries are most common in woodworking helps you stay prepared for emergencies. These injuries include cuts, punctures, burns, eye injuries, and crush injuries from heavy tools or wood pieces.

Understanding the injury type is the first step in providing proper first aid before professional help arrives. It’s essential to keep calm and assess the situation quickly to prevent further harm.

Essential First Aid Steps for Woodworking Injuries

1. Cuts and Lacerations

Minor cuts can often be treated on-site, but deeper wounds require prompt medical attention. For cuts:

- Stop the bleeding: Apply direct pressure using a clean cloth or bandage.

- Clean the wound: Use clean water to rinse away dirt and debris gently.

- Protect the wound: Cover it with sterile gauze or a bandage to prevent infection.

- Seek medical care: If the cut is deep, bleeding heavily, or caused by rusty or dirty objects, get professional treatment immediately.

2. Puncture Wounds

Puncture wounds can be deceptive because they may appear small but go deep into the tissue, increasing the risk of infection.

- Do not remove embedded objects: Removing items lodged in the wound can worsen bleeding.

- Control bleeding: Apply gentle pressure around the wound site.

- Clean around the wound carefully: Use antiseptic wipes or clean water, avoiding the puncture hole itself.

- Seek immediate medical care: Tetanus shots may be required depending on your vaccination history and the object’s condition.

3. Burns

Burns from hot tools or chemicals can cause painful skin damage. Respond promptly by:

- Cooling the burn: Use cool (not cold) running water for at least 10 to 20 minutes.

- Covering the burn: Use a clean, non-stick dressing or cloth to protect the skin.

- Avoiding ointments: Do not apply creams or greasy substances to severe burns.

- Getting professional help: For burns that are large, blistered, or involve the face or hands, seek immediate care.

4. Eye Injuries

Eye injuries are common in woodworking due to flying wood chips or sawdust. First aid includes:

- Do not rub the eyes: This can worsen the injury.

- Flush with water: Use clean, lukewarm water or saline solution to rinse out debris for at least 15 minutes.

- Cover the eye: Use a sterile eye pad or clean cloth to shield the injured eye.

- Seek urgent medical evaluation: Eye injuries need prompt professional care to prevent complications.

5. Crush Injuries

Crush injuries can cause severe damage and require swift, thorough action:

- Assess for bleeding or fractures: If bleeding cannot be controlled or bones may be broken, avoid moving the injured limb unnecessarily.

- Apply pressure and immobilize: Use clean cloths for bleeding control and splints for stabilization.

- Call emergency services immediately: These injuries often need hospitalization and advanced care.

Emergency Contact and Preparation

Before starting any woodworking project, have an emergency plan in place. Keep a well-stocked first aid kit nearby, and ensure you know the quickest way to call for help.

Create an emergency contact list, including local hospitals and poison control centers. Additionally, inform coworkers or family members about your projects so they can assist swiftly if needed.

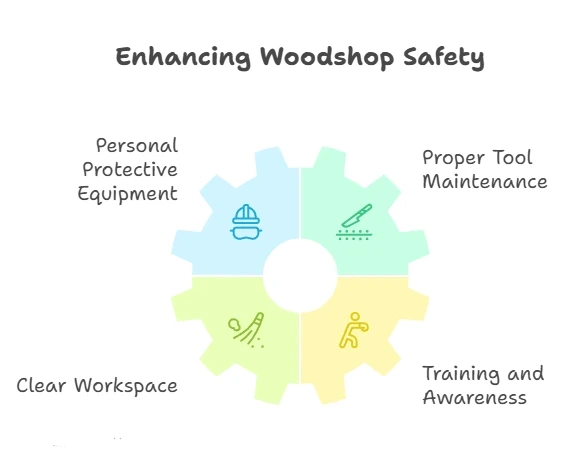

How to Prevent Fatal Accidents in Woodshops

| Safety Practice | Purpose | Key Tips |

|---|---|---|

| Use of Personal Protective Equipment (PPE) | To protect skin, eyes, and respiratory system | Always wear safety glasses, gloves, ear protection, and dust masks |

| Proper Tool Maintenance | To prevent malfunctions leading to accidents | Sharpen blades regularly and inspect for damage |

| Clear Workspace | To reduce trip and collision hazards | Keep floors clean, and remove scrap wood immediately |

| Training and Awareness | To ensure correct tool usage and hazard identification | Attend workshops and read manuals before using equipment |

Additional Resources for Woodworking Safety and First Aid

Learning more about veterinary woodworking safety and emergency care can enhance your preparedness and confidence. Visit these trusted sites for extensive guides and training:

- OSHA Woodworking Safety Guidelines

- Woodworkers Institute First Aid Tips

- National Safety Council – First Aid at Work

Keeping these emergency procedures and first aid techniques in mind is essential for anyone working with wood. Acting quickly and correctly during woodworking accidents saves lives and reduces the chance of prolonged injury. Always prioritize safety and preparation to make your woodworking

Conclusion

Staying safe while woodworking is not just a smart choice—it’s vital for enjoying your craft without injury. By following essential woodworking safety tips, you protect yourself from common hazards that can quickly turn a fun project into a serious accident.

Always choose the right personal protective equipment like safety glasses, ear protection, and dust masks to shield yourself from flying debris, loud noise, and harmful dust. Proper handling and maintenance of your tools ensure they work efficiently and reduce the chance of unexpected malfunctions.

Keeping your workspace organized and free of clutter creates a safer environment where you can focus on your work without unnecessary distractions or tripping hazards. knowing emergency procedures and basic first aid steps prepares you to respond quickly if an accident occurs, minimizing the severity of injuries.

Putting these safety practices into action will help you enjoy woodworking with confidence and peace of mind. Remember, safety is the foundation that lets your creativity thrive. Every careful step you take protects your hands, eyes, and health, so you can keep building beautiful projects for years to come.

When working with wood, safety should be your top priority. Wearing the right safety gear can protect you from various hazards like flying wood chips, dust, and accidental cuts. Always wear safety glasses or goggles to shield your eyes. Wood dust can irritate your eyes and lead to long-term vision problems, so this simple step is crucial.

In addition to eye protection, use hearing protection such as earplugs or earmuffs. Power tools generate high noise levels that could damage your hearing over time. Dust masks or respirators help prevent inhalation of harmful wood dust, which can affect your lungs.

Don’t forget to wear appropriate clothing. Avoid loose sleeves or jewelry that could catch on machinery. Wearing sturdy, closed-toe shoes protects your feet from dropped tools or nails. Gloves might be useful, but be cautious when operating machines, as gloves can sometimes get caught, increasing the risk of injury.

Safe Handling and Operation of Woodworking Tools

One of the most essential practices in woodworking is knowing your tools well. Whether you’re using saws, drills, or sanders, always read the manufacturer’s instructions before starting. Check all equipment for damage or wear before use. Faulty tools can lead to accidents and poor workmanship.

Maintain sharp blades and bits. Dull tools can slip or require excessive force, increasing the chance of injury. Replace or sharpen blades as needed to ensure clean cuts.

When operating power tools, always use guards and safety features. Never remove or bypass them. For example, blade guards and anti-kickback devices on saws are designed to keep your hands safe and prevent kickback injuries.

Keep your hands away from moving parts and cutting edges. Use push sticks or push blocks when feeding wood into saws to keep your hands safe.

How to Set Up a Safe Workspace

Your workspace plays a significant role in maintaining safety. Keep your area clean and free from clutter to avoid tripping hazards. Good lighting is essential—working in a dim area can lead to mistakes and accidents.

Arrange tools and materials so they are within easy reach but not overcrowded. Cords should be neatly organized and out of walking paths to prevent tripping.

If possible, install dust extraction systems or use portable dust collectors. These help keep your workspace clean and reduce airborne wood dust, protecting your respiratory health.

Ensure all electrical outlets and tools are properly grounded. Faulty wiring or power surges can cause shocks or fires.

Critical Practices to Follow While Woodworking

- Stay Focused: Avoid distractions. Pay close attention when operating tools. Keeping your mind on the task helps prevent accidents.

- Use Proper Techniques: Don’t force tools. Let the blade or bit do the work at its own pace. This reduces strain and lessens the chance of slips.

- Keep Both Hands on Tools: Maintain a firm grip and balanced stance. This control is vital for precise and safe cuts.

- Disconnect Power: Always unplug tools before changing blades, bits, or performing maintenance.

- Follow Manufacturer Safety Instructions: They provide tested methods to use tools safely and effectively.

Common Woodworking Hazards and How to Avoid Them

| Hazard | Cause | Prevention |

|---|---|---|

| Flying Debris | Cutting, sanding, or chopping wood | Wear eye protection; use dust masks |

| Kickback | Blade catches wood and throws it back | Use blade guards, hold wood firmly, use push sticks |

| Hearing Damage | Prolonged noise from power tools | Wear hearing protection |

| Electric Shock | Faulty wiring or wet environment | Inspect cords, use GFCI outlets, keep area dry |

| Lung Issues | Inhalation of wood dust | Use respirators or dust masks; ventilate workspace |

Additional Tips for Woodworking Safety

Keep a first aid kit handy in your workspace to handle minor injuries quickly. Knowing basic first aid boosts your confidence and can minimize complications from accidents.

Don’t work when you’re tired or under the influence of alcohol or drugs. Fatigue and impaired judgment increase the risk of mistakes and injuries. Take breaks to rest your muscles and eyes during long sessions.

Consider taking a woodworking safety course, especially if you’re new to the craft. These courses provide hands-on experience and teach you how to work confidently with tools.

For more detailed guidelines and safety resources, you can visit Woodworking Safety 101 or browse safety standards at OSHA Woodworking Safety.

Choosing the Right Personal Protective Equipment for Woodworking

Essential Gear for Protecting Your Eyes

When working with wood, the tiniest chips or dust particles can fly up and cause serious eye injuries. Choosing the right eye protection is crucial for your safety. Look for safety goggles or impact-resistant glasses that fully cover your eyes and fit comfortably. Glasses with side shields provide extra protection from debris coming from different angles.

For those using power tools like saws, planers, or routers, goggles with anti-fog coating are ideal. They ensure you maintain clear vision without constantly stopping to wipe off moisture or dust. If you wear prescription glasses, consider goggles that fit over them or specialized safety glasses with your prescription.

Protective Respiratory Gear to Keep Your Lungs Safe

Wood dust contains particles that can irritate your lungs or cause long-term respiratory problems. Wearing the right mask or respirator helps you avoid inhaling these harmful materials.

- Dust masks: For light wood dust exposure, disposable dust masks rated N95 are a good choice. They filter out most airborne particles but are not suitable for chemical vapors.

- Respirators: When working with finishes, stains, or solvents, use a respirator with cartridges designed to filter both dust and fumes. Half-face respirators provide better protection in these scenarios.

Make sure your mask fits snugly to prevent air leaks. Facial hair can reduce the effectiveness of respirators, so consider shaving if you are using these frequently.

Choosing the Right Hearing Protection

Woodworking tools can produce noise levels that may damage your hearing over time. Consistent exposure without ear protection can lead to permanent hearing loss. To stay safe:

- Earplugs: These are small, inexpensive, and easy to wear. They block harmful noise but allow you to hear important sounds around you.

- Earmuffs: Provide a higher level of noise reduction and are comfortable for extended wear. Some advanced models feature electronic sound control to filter noise selectively.

It may be worth trying both options to see which fits more comfortably during long woodworking sessions.

Hand and Arm Safety Equipment

Your hands are your most valuable tools in woodworking, which means protecting them is vital. Different tasks call for different types of gloves designed to provide a balance of protection and dexterity.

| Glove Type | Best For | Protection Level |

|---|---|---|

| Leather gloves | Handling rough wood, splinters, and sharp edges | High cut resistance and durability |

| Cut-resistant gloves (Kevlar or similar) | Using sharp blades and precision work | Superior cut and puncture protection |

| Nitrile-coated gloves | Handling finishes, stains, or adhesives | Good chemical resistance and grip |

Always avoid loose gloves near rotating tools to prevent entanglement injuries. For fine carving or sanding, using gloves may reduce your grip and precision, so be mindful of the task requirements.

Footwear and Clothing for a Safe Workshop

Protective footwear is often overlooked but essential when working around heavy wood pieces and sharp tools. Steel-toe boots or shoes provide critical protection against dropped objects and punctures.

Wear clothing that fits well without loose sleeves or dangling parts. Loose clothing can catch in machinery, posing a serious safety risk. Durable, long-sleeved shirts and pants made from natural fibers help shield your limbs from minor cuts and abrasions.

Additional Safety Accessories

Other useful items that help enhance your safety while woodworking include:

- Face shields: For heavy-duty work or when grinding, a full-face shield protects your face from flying debris.

- Aprons: Heavy-duty canvas or leather aprons guard against splinters and spills.

- First aid kit: Keep a kit nearby with supplies for cuts, splinters, and eye rinsing solutions.

Before starting any woodworking project, it’s best to review your personal protective equipment to make sure it’s suitable and in good condition. When in doubt, refer to trusted resources like the OSHA woodworking safety guidelines for detailed recommendations on the proper PPE.

Choosing the right personal protective equipment creates a safer work environment, reduces accidents, and ensures you enjoy woodworking with confidence and peace of mind. Remember, investing time in selecting and properly using protective gear is just as important as your skills and tools.

Safe Handling and Maintenance of Woodworking Tools

Essential Practices for Handling Woodworking Tools Safely

Working with woodworking tools can be rewarding, but safety should always come first. Proper handling of equipment like saws, chisels, and planes prevents accidents and ensures the quality of your craft. When you handle woodworking tools, always keep your focus sharp and your hands steady. Avoid distractions, and never operate tools if you feel tired or unwell.

Here are key points to remember when using woodworking tools safely:

- Wear Personal Protective Equipment (PPE): Always use safety glasses to protect your eyes from flying debris, hearing protection when using loud power tools, and gloves if recommended for the task.

- Maintain a Clean Workspace: Keep your workbench free from clutter. Tools and materials scattered around can cause trips or slips.

- Check Tools Before Use: Inspect blades, cords, and handles for damage or wear. Dull blades increase the risk of accidents, so sharpen or replace them as needed.

- Use Tools for Their Intended Purpose: Do not use a chisel as a screwdriver or an inappropriate saw blade on the wrong material.

- Secure Wood Properly: Clamp your workpiece firmly to prevent movement during cutting, sanding, or shaping.

Routine Maintenance to Keep Tools in Optimal Condition

Good maintenance of woodworking tools is vital for your safety and the tools’ longevity. Neglecting maintenance can lead to tool failure and poor-quality work. Create a regular schedule to clean, sharpen, and store tools properly.

Cleaning and Lubricating

After each use, clean tools with a dry cloth to remove sawdust and resin build-up. You can use a soft brush or compressed air for intricate parts. Apply a thin layer of lubricant or oil (such as camellia oil or machine oil) to metal components to prevent rust. Avoid excessive oiling, which can attract dust.

Sharpening Blades and Cutting Edges

Sharp blades not only improve precision but also reduce the effort required, lowering the chance of slips or mistakes. Use a sharpening stone, honing guide, or an electric sharpener, following the manufacturer’s guidelines. Remember that dull blades can “grab” wood unexpectedly, risking injury.

Electrical Tool Care

For power tools, inspect the electrical cords regularly for cuts or frays. Replace damaged cords immediately to avoid electrical hazards. Ensure that moving parts like belts and motors are cleaned and lubricated according to the tool’s manual. Never operate tools with grounding issues or exposed wires.

Proper Storage Techniques to Enhance Safety

Proper storage not only protects your tools but also helps prevent accidents caused by misplaced sharp objects.

| Storage Method | Tools Suitable | Benefits |

|---|---|---|

| Wall-mounted racks or pegboards | Hand tools like chisels, hammers, screwdrivers | Easy access, visibility, keeps tools off work surfaces |

| Toolboxes with foam inserts | Precision tools, small power tools | Protects delicate parts and prevents shifting |

| Blade guards and sheathes | Saws, planes, knives | Prevents accidental cuts and blade damage |

If you lack adequate space, consider portable cases with cushioning to transport tools safely between locations.

Ergonomics and Safe Posture to Reduce Risks

Handling tools effectively also depends on your posture and the ergonomics of your workspace. Position yourself so that you have a stable footing and easy reach of tools and materials. Avoid awkward angles that strain your wrists, arms, or back. Adjustable workbenches and anti-fatigue mats help reduce fatigue during long woodworking sessions.

Learning and Continuous Improvement

Educating yourself about tool safety and maintenance is an ongoing process. Many woodworking communities and websites provide free tutorials and safety checklists.

For trusted and detailed guidance, visit the Occupational Safety and Health Administration (OSHA) woodworking safety page. It covers industry-standard practices and tips.

You can also explore the Popular Woodworking safety resources, which offer expert advice on handling and maintaining woodworking tools with care.

Key Safety Reminders

- Never rush your work—patience reduces accidents.

- Disconnect power tools from electricity before adjusting or cleaning.

- Store tools in places inaccessible to children or untrained individuals.

- Use push sticks or feather boards when guiding small wood pieces near blades.

- Stay hydrated and take breaks to maintain focus and alertness.

Remember that investing time in the safe handling and maintenance of your woodworking tools is an investment in your well-being and the quality of your craftsmanship. Keeping these practices top of mind makes your woodworking both safer and more enjoyable.

Creating a Hazard-Free Workspace for Woodworking Projects

Essential Steps to Establish a Safe Woodworking Environment

When you set up your woodworking area, safety should be the foundation of every decision. A hazard-free workspace not only protects you but also boosts your productivity by minimizing interruptions caused by accidents. Here’s how to create an environment where you can work confidently and safely on your woodworking projects.

Choose the Right Location and Layout

Start by selecting a dedicated space with plenty of room to move freely around your tools and materials. Crowded areas increase the risk of trips and accidental contact with sharp equipment. Organize your workspace so that each tool has a clear, accessible place. Keep frequently used items within easy reach while storing other supplies safely away to avoid clutter.

Ensure Proper Lighting and Ventilation

Good lighting helps you see clearly and reduces mistakes that could cause injury. Position bright, shadow-free lights over your worktables and cutting areas. Avoid dim corners where visibility may be poor.

Woodworking creates fine dust and fumes from finishes and adhesives. To protect your lungs and maintain air quality, make sure your workspace is well ventilated. Use exhaust fans, open windows, or air filtration systems designed for workshop environments to keep the air clean.

Set Up a Tool Safety Zone

Power tools and hand tools are essential but can be dangerous if mishandled. Design a dedicated tool zone with safety in mind:

- Use sturdy workbenches with clamps to secure pieces and prevent shifts during cutting or sanding.

- Install guards on machines like table saws and jointers to reduce accidental contact with blades.

- Keep sharp tools like chisels and knives sheathed or in designated holders when not in use.

Maintain a Clean and Organized Workspace

Dust and wood scraps can clutter your area, creating slipping hazards or fire risks. Develop a routine to sweep floors and work surfaces regularly. Use a dust collector or shop vacuum to remove fine particles immediately after sanding or cutting. In addition, keep all chemical adhesives, stains, and finishes in clearly labeled containers, stored safely away from heat sources and out of reach of children or pets.

Establish Clear Safety Protocols

Having rules and procedures reduces guesswork and increases consistency in safe practices. Some helpful protocols to implement include:

| Safety Practice | Description | Benefits |

|---|---|---|

| Personal Protective Equipment (PPE) | Always wear safety goggles, hearing protection, dust masks, and gloves. | Prevents injuries to eyes, ears, skin, and respiratory system. |

| Tool Inspection | Check all tools before use for damage or wear. | Detects potential malfunctions early, preventing accidents. |

| Electrical Safety | Ensure cords are intact and outlets aren’t overloaded. | Reduces risk of electrical shocks and fires. |

| Emergency Readiness | Have a first-aid kit and fire extinguisher readily accessible. | Allows quick response to accidents or fires. |

Use Signage and Labels for Awareness

Visual reminders can reinforce safe behavior. Use clear, easy-to-read signs near hazardous areas or equipment to highlight risks. Label drawers, shelves, and containers so you and anyone else working in the shop know where everything belongs. This practice limits time spent searching for tools and lowers the chance of misplaced objects causing accidents.

Take Advantage of Quality Storage Solutions

Investing in proper storage systems helps maintain an orderly workspace. Consider the following options:

- Wall-mounted racks for clamps and hand tools.

- Lockable cabinets for chemicals and sharp accessories.

- Mobile carts to move tools safely between workstations.

Regular Maintenance and Inspections

Prevent hazards by scheduling routine checks on your workshop setup. Sharpen blades, lubricate moving parts, and replace worn-out safety features before problems arise. Keeping everything in top condition improves efficiency and cuts down on unexpected downtime caused by tool failure or accidents.

Learn More About Woodworking Safety

Expanding your knowledge can empower you to make safer choices. Trusted resources like the American Woodworking Association offer guidelines, courses, and updates on best safety practices. Additionally, the Occupational Safety and Health Administration (OSHA) provides detailed regulations and tips specifically for woodworking environments.

Creating a Hazard-Free Workspace Requires Planning, Commitment, and Ongoing Effort

By following these tips, you can protect yourself and enjoy your woodworking projects with confidence and peace of mind.

Emergency Procedures and First Aid in Woodworking Accidents

Recognizing Common Woodworking Injuries

Woodworking is a rewarding craft but carries inherent risks that require immediate and effective action when accidents happen. Knowing what type of injuries are most common in woodworking helps you stay prepared for emergencies. These injuries include cuts, punctures, burns, eye injuries, and crush injuries from heavy tools or wood pieces.

Understanding the injury type is the first step in providing proper first aid before professional help arrives. It’s essential to keep calm and assess the situation quickly to prevent further harm.

Essential First Aid Steps for Woodworking Injuries

1. Cuts and Lacerations

Minor cuts can often be treated on-site, but deeper wounds require prompt medical attention. For cuts:

- Stop the bleeding: Apply direct pressure using a clean cloth or bandage.

- Clean the wound: Use clean water to rinse away dirt and debris gently.

- Protect the wound: Cover it with sterile gauze or a bandage to prevent infection.

- Seek medical care: If the cut is deep, bleeding heavily, or caused by rusty or dirty objects, get professional treatment immediately.

2. Puncture Wounds

Puncture wounds can be deceptive because they may appear small but go deep into the tissue, increasing the risk of infection.

- Do not remove embedded objects: Removing items lodged in the wound can worsen bleeding.

- Control bleeding: Apply gentle pressure around the wound site.

- Clean around the wound carefully: Use antiseptic wipes or clean water, avoiding the puncture hole itself.

- Seek immediate medical care: Tetanus shots may be required depending on your vaccination history and the object’s condition.

3. Burns

Burns from hot tools or chemicals can cause painful skin damage. Respond promptly by:

- Cooling the burn: Use cool (not cold) running water for at least 10 to 20 minutes.

- Covering the burn: Use a clean, non-stick dressing or cloth to protect the skin.

- Avoiding ointments: Do not apply creams or greasy substances to severe burns.

- Getting professional help: For burns that are large, blistered, or involve the face or hands, seek immediate care.

4. Eye Injuries

Eye injuries are common in woodworking due to flying wood chips or sawdust. First aid includes:

- Do not rub the eyes: This can worsen the injury.

- Flush with water: Use clean, lukewarm water or saline solution to rinse out debris for at least 15 minutes.

- Cover the eye: Use a sterile eye pad or clean cloth to shield the injured eye.

- Seek urgent medical evaluation: Eye injuries need prompt professional care to prevent complications.

5. Crush Injuries

Crush injuries can cause severe damage and require swift, thorough action:

- Assess for bleeding or fractures: If bleeding cannot be controlled or bones may be broken, avoid moving the injured limb unnecessarily.

- Apply pressure and immobilize: Use clean cloths for bleeding control and splints for stabilization.

- Call emergency services immediately: These injuries often need hospitalization and advanced care.

Emergency Contact and Preparation

Before starting any woodworking project, have an emergency plan in place. Keep a well-stocked first aid kit nearby, and ensure you know the quickest way to call for help.

Create an emergency contact list, including local hospitals and poison control centers. Additionally, inform coworkers or family members about your projects so they can assist swiftly if needed.

How to Prevent Fatal Accidents in Woodshops

| Safety Practice | Purpose | Key Tips |

|---|---|---|

| Use of Personal Protective Equipment (PPE) | To protect skin, eyes, and respiratory system | Always wear safety glasses, gloves, ear protection, and dust masks |

| Proper Tool Maintenance | To prevent malfunctions leading to accidents | Sharpen blades regularly and inspect for damage |

| Clear Workspace | To reduce trip and collision hazards | Keep floors clean, and remove scrap wood immediately |

| Training and Awareness | To ensure correct tool usage and hazard identification | Attend workshops and read manuals before using equipment |

Additional Resources for Woodworking Safety and First Aid

Learning more about veterinary woodworking safety and emergency care can enhance your preparedness and confidence. Visit these trusted sites for extensive guides and training:

- OSHA Woodworking Safety Guidelines

- Woodworkers Institute First Aid Tips

- National Safety Council – First Aid at Work

Keeping these emergency procedures and first aid techniques in mind is essential for anyone working with wood. Acting quickly and correctly during woodworking accidents saves lives and reduces the chance of prolonged injury. Always prioritize safety and preparation to make your woodworking

Conclusion

Staying safe while woodworking is not just a smart choice—it’s vital for enjoying your craft without injury. By following essential woodworking safety tips, you protect yourself from common hazards that can quickly turn a fun project into a serious accident.

Always choose the right personal protective equipment like safety glasses, ear protection, and dust masks to shield yourself from flying debris, loud noise, and harmful dust. Proper handling and maintenance of your tools ensure they work efficiently and reduce the chance of unexpected malfunctions.

Keeping your workspace organized and free of clutter creates a safer environment where you can focus on your work without unnecessary distractions or tripping hazards. knowing emergency procedures and basic first aid steps prepares you to respond quickly if an accident occurs, minimizing the severity of injuries.

Putting these safety practices into action will help you enjoy woodworking with confidence and peace of mind. Remember, safety is the foundation that lets your creativity thrive. Every careful step you take protects your hands, eyes, and health, so you can keep building beautiful projects for years to come.