ATTENTION: World's Largest Collection of 16,000 Woodworking Plans!

Stop struggling with incomplete plans that waste your time and money!

Step-by-step instructions that make woodworking super easy, even for beginners

Detailed schematics, cutting lists, and materials lists for every project

Get new plans monthly for life - no recurring fees or hidden costs

Request custom plans for your unique projects at no extra charge

Get 4 valuable bonuses including woodworking guides and business tips

GET INSTANT ACCESS NOW!

ATTENTION: World's Largest Collection of 16,000 Woodworking Plans!

Stop struggling with incomplete plans that waste your time and money!

Step-by-step instructions that make woodworking super easy, even for beginners

Detailed schematics, cutting lists, and materials lists for every project

Get new plans monthly for life - no recurring fees or hidden costs

Request custom plans for your unique projects at no extra charge

Get 4 valuable bonuses including woodworking guides and business tips

GET INSTANT ACCESS NOW!

When diving into woodworking, choosing the right plans for your woodworking bench is crucial. A well-designed bench will enhance your crafting experience and improve your efficiency. Here are some essential features to consider when selecting woodworking bench plans.

Functionality

The first thing you should consider is the functionality of the bench. Think about what type of woodworking tasks you often undertake. Will you be doing joinery, sanding, or assembly? A functional bench is designed to cater to the specific needs of your projects, offering you the right features to facilitate those tasks.

Size and Space

Next, assess the size of your workspace. A compact area will require woodworking bench plans that accommodate smaller designs. Measure your available space and choose a plan that allows you to work comfortably without feeling cramped. Here’s a quick guide to help you:

| Space Available | Recommended Bench Size |

|---|---|

| Up to 4 ft² | 3 to 4 ft long |

| 4 to 8 ft² | 4 to 6 ft long |

| Above 8 ft² | 6+ ft long |

Materials

The material used for your bench significantly impacts its durability and stability. Common materials include hardwood, plywood, or a combination of both. Hardwood offers strength, while plywood can be more cost-effective. Ensure the plans specify quality materials that suit your budget while providing the necessary strength. Additionally, consider recycled materials if you’re looking for an environmentally friendly option.

Height

The bench height is an often-overlooked aspect that can affect your posture and comfort. Standard woodworking benches range from 28 to 36 inches high. The best way to determine the right height is to measure from the floor to your elbow when standing. Having a bench that matches this measurement will help in reducing strain on your back and arms.

Versatility

Choose plans that allow for modifications and adaptability. A versatile bench will serve multiple functions, such as a workbench, assembly area, and finishing station. Look for designs that incorporate built-in storage or areas where you can attach different tools, such as vises and clamps.

Design Complexity

The complexity of the woodworking plans can significantly influence your decision. If you are a beginner, opt for simpler designs with clear instructions. Advanced woodworkers may enjoy intricate designs that challenge their skills. Pay attention to reviews or user experiences with the plans to gauge their clarity and feasibility.

Stability and Weight

Stability is critical for any woodworking bench. Look for plans that emphasize a sturdy base or thick legs. This stability will remain essential when you’re applying significant pressure while cutting or sanding. Heavier benches offer better stability; however, ensure they aren’t too heavy for you to move if necessary.

Storage Options

Having adequate storage on your woodworking bench can improve organization and accessibility. Many woodworking bench plans include drawers, shelves, or compartments for tools and materials. Evaluate how much storage you need based on the projects you typically undertake.

For more detailed plans and ideas, you can explore websites like Wood Magazine or Popular Woodworking, both of which offer a variety of plans and tips to help you choose the best woodworking bench for your needs.

As you review your options, consider your specific needs carefully. Prioritize the features that cater to your style and projects. Choosing the right woodworking bench plans is an investment in your craft, ensuring you have a reliable workspace that encourages creativity and efficiency.

Benefits of Customizing Your Woodworking Bench Design

When it comes to woodworking, having the right workspace is crucial. A woodworking bench is often the centerpiece of any shop, and customizing its design offers numerous advantages. Unique designs tailored to your specific needs can greatly enhance your woodworking experience.

One significant benefit of customizing your woodworking bench is improved functionality. A bench tailored to your work habits allows for a smoother workflow. You can incorporate features that suit your preferred techniques, such as:

- Storage Solutions: Drawers or compartments for tools and materials can declutter your space.

- Height Adjustments: Having an adjustable height feature allows you to work comfortably whether you’re standing or sitting.

- Built-in Vises: A personalized setup can include vises that accommodate specific projects.

Additionally, customizing your woodworking bench can enhance efficiency. Think about it: when everything is within reach and organized, you spend less time searching for tools and materials. You can pinpoint your most-used equipment and design your bench layout accordingly. This means your time spent working on projects can be maximized.

Another key advantage is the comfort that comes from a personalized design. Everyone has different working styles, and a bench that reflects your preferences can reduce strain and fatigue during long sessions. If you’re tall, a higher work surface can minimize back strain; if you focus on intricate details, custom ergonomic features can help you maintain precision without discomfort.

People often overlook aesthetics when customizing their benches. A well-designed workspace not only motivates you but also enhances your shop’s atmosphere. Choose colors, textures, and styles that inspire you! A visually pleasing environment can motivate you to spend more time on your woodworking projects.

Moreover, crafting your unique woodworking bench can be a fulfilling project in itself. This process allows you to apply your skills, use your creativity, and ultimately create something that is uniquely yours. When you design and build your bench, you are also honing your woodworking capabilities, which is invaluable for upcoming projects.

- Custom dimensions ensure that your bench fits perfectly into your shop space.

- You can select quality materials that will ensure the longevity of your bench.

- Specialized features catered to your projects.

While you may find numerous woodworking bench plans online, customization means you don’t have to conform to standard sizes or layouts. You can look at Wood Magazine to discover different perspectives on customization. This flexibility is invaluable, especially if you have limited space or specific tasks you regularly perform.

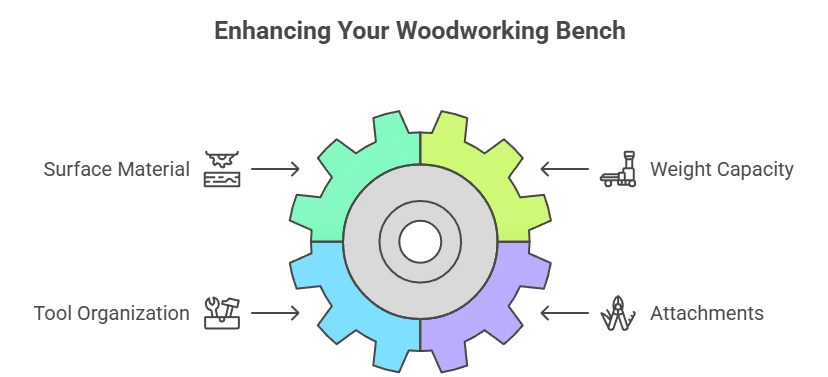

Here’s a quick overview of considerations when customizing your woodworking bench:

| Feature | Description | Benefit |

|---|---|---|

| Surface Material | Choose between hardwood, laminate, or MDF. | Durability and ease of cleaning. |

| Weight Capacity | Design a structure to support heavy projects. | Prevents wobbling or tipping. |

| Tool Organization | Plan for drawer space or magnetic strips. | Easy access to necessary tools. |

| Attachments | Integrate clamps, jigs, or custom vises. | Increases versatility and efficiency. |

Safety is another benefit of a customized woodworking bench. By incorporating features that suit your style, you can create a safer workspace. A bench that fits your needs may help prevent accidents, as you’ll be less likely to reach awkwardly or fumble with tools.

Customizing your woodworking bench creates a workspace that aligns with your needs, improving functionality, efficiency, comfort, and safety. This investment not only enhances your workspace but also enriches your woodworking journey. Check out options for woodworking bench plans at Woodworker Source to explore the endless possibilities of designs you can make uniquely yours.

Comparing Different Types of Woodworking Benches: Which is Right for You?

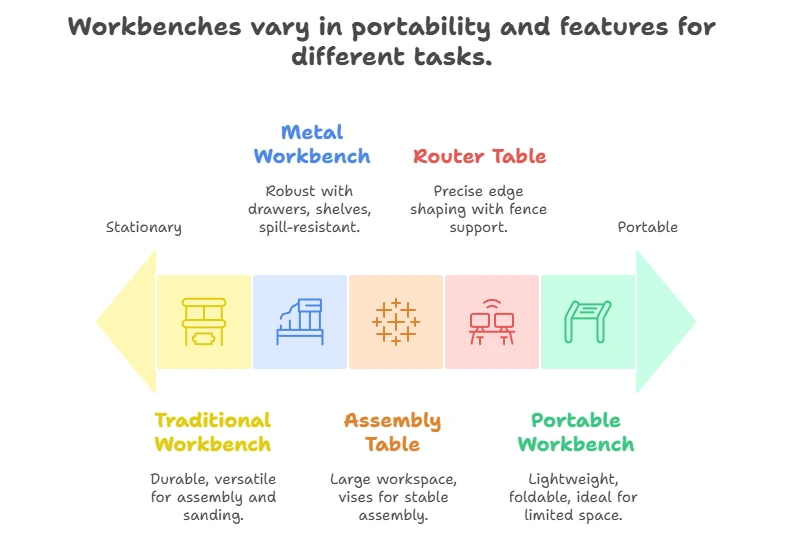

When it comes to woodworking, choosing the right bench can greatly enhance your project efficiency and comfort. There are various types of woodworking benches available, each designed for specific tasks and needs. Understanding the differences between these benches will help you select one that best fits your woodworking style.

Types of Woodworking Benches

Below are the most common types of woodworking benches available, each with unique characteristics:

- Traditional Workbenches: These benches offer a solid, flat surface that is perfect for a wide range of tasks, from assembly to sanding. Typically featuring dog holes for clamping, they provide versatility and durability.

- Portable Workbenches: Lightweight and easy to move, these benches are great for both indoor and outdoor projects. They often fold up for easy storage, making them ideal if space is limited.

- Metal Workbenches: Metal benches are robust and usually come with drawers and shelves. While they are not as traditional as wooden options, they provide great durability and are often resistant to spills and stains.

- Router Tables: Specifically designed for routing, these benches provide extra support when shaping edges. They often come equipped with fences for precision cuts.

- Assembly Tables: These benches are larger and specifically designed for assembling various parts. They offer ample workspace and can be equipped with vises for additional stability.

Choosing the Right Bench

Your choice of a woodworking bench will largely depend on the type of projects you intend to undertake. Here are some factors to consider:

1. Size and Space

Before making a purchase, assess the space you have available. If you’re limited on room, a portable or foldable bench may be your best option. For dedicated workshops, a traditional or assembly bench could work well.

2. Stability and Durability

Your bench needs to withstand the rigors of woodworking. A heavier bench usually offers more stability, which is crucial for precision tasks. For instance, traditional woodworking benches made from solid hardwoods are known for their longevity and sturdiness.

3. Versatility

Consider how multi-functional you want your bench to be. If you plan to tackle various projects, opt for a bench that adapts to multiple woodworking techniques. This could mean selecting a traditional bench with various add-ons, or a portable one that can easily be adjusted for different tasks.

4. Budget

Woodworking benches come in a range of prices. Decide how much you are willing to invest and explore options within that budget. Sometimes building your own bench can be a cost-effective and rewarding solution.

Top Recommended Benches

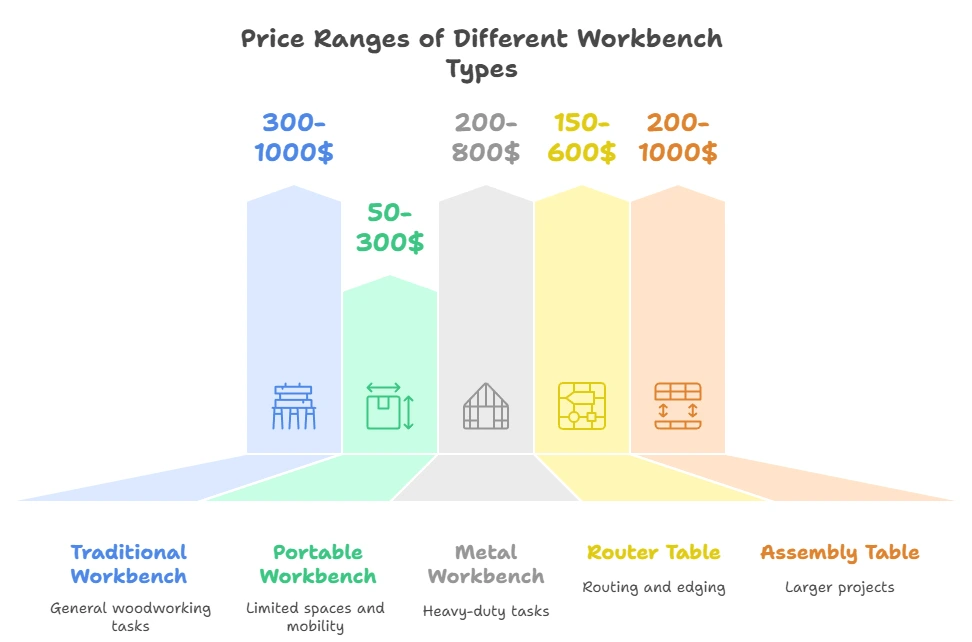

| Bench Type | Best For | Price Range |

|---|---|---|

| Traditional Workbench | General woodworking | $300 – $1000 |

| Portable Workbench | Limited spaces / mobility | $50 – $300 |

| Metal Workbench | Heavy-duty tasks | $200 – $800 |

| Router Table | Routing and edging | $150 – $600 |

| Assembly Table | Larger projects | $200 – $1000 |

For more inspiration and plans, visit Wood Magazine or check out Popular Woodworking for helpful resources.

Finding the right woodworking bench involves an understanding of your specific needs and workspace. Whether you’re a casual DIYer or a seasoned craftsman, having the right tools, including a reliable bench, will undeniably enhance your woodworking experience.

Tips for Effectively Building Your Own Woodworking Bench

Building your own woodworking bench can be one of the most rewarding projects for any woodworker. Not only does it provide a functional workspace, but it also allows you to tailor the bench to your specific needs. Here are some effective tips to guide you through the process of creating a woodworking bench that meets your requirements.

Determine Your Bench Size

The first step in building your woodworking bench is deciding on its size. Think about what you will use the bench for and how much space you have available. Here are a few points to consider:

- Work Area: Ensure the bench is long and wide enough to accommodate your projects comfortably.

- Height: The ideal height is typically at your waist level. This way, you can work comfortably without straining.

- Storage: Consider if you need built-in storage for tools and supplies.

Select the Right Material

Choosing the right materials is crucial for building a durable and functional woodworking bench. Here are some materials to consider:

- Hardwood: Maple or beech provides durability and a smooth surface.

- Plywood: A great option for the work surface; it’s cost-effective and strong.

- Metal Components: Steel can be used for the legs and support to create a sturdy base.

Designing the Bench

Now that you have the size and materials in mind, it’s time to plan your bench’s design. There are many woodworking bench plans available, from simple to complex. You might want to look at plans from Wood Magazine to find something that fits your skills and needs.

Tools You’ll Need

Before starting your project, make sure you have all the necessary tools. This list will help you gather everything needed:

- Table saw

- Miter saw

- Drill

- Screwdrivers

- Clamps

- Sander

Follow Safety Precautions

Safety should always be a priority when working with tools and materials. Here are some essential safety tips:

- Always wear eye protection and dust masks.

- Ensure that your workspace is clean and free of distractions.

- Familiarize yourself with each tool’s safety features before using them.

Assemble with Care

When you start assembling your woodworking bench, take your time to ensure everything fits together properly. Here are some assembly tips:

- Start with the frame: Build the bench frame first for stability.

- Use glue and screws: This will provide extra strength to the joints.

- Check for level: Make sure your bench is level before securing everything in place.

Finishing Touches

Consider applying a finish to protect your woodworking bench. A simple oil finish can enhance the wood’s natural beauty and offer protection against spills and stains. Additionally, think about adding vises or other accessories to enhance functionality. You can find more information about finishes at Woodworker’s Source.

Regular Maintenance

Once your woodworking bench is complete, ongoing maintenance is key to preserving its look and functionality. Here are some maintenance tips:

- Regularly clean your bench with a damp cloth.

- Reapply finish as needed to protect the wood.

- Inspect for any damages or wear regularly and fix them promptly.

Building your own woodworking bench can greatly enhance your crafting experience. By following these tips, you’ll create a workspace that is not only efficient but also inspires creativity.

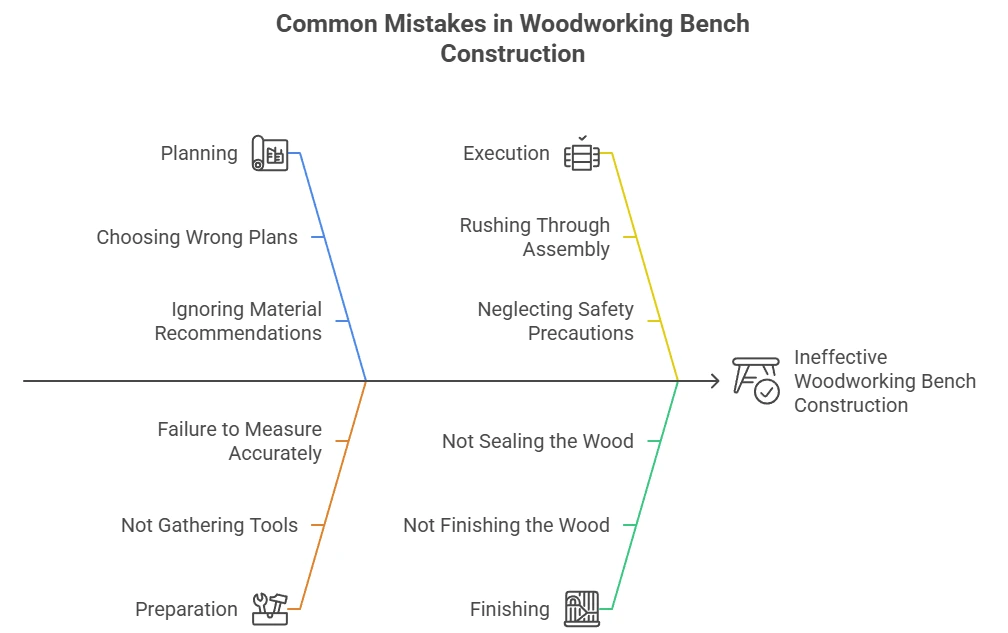

Common Mistakes to Avoid When Following Woodworking Bench Plans

Woodworking can be a rewarding hobby, but it often comes with its share of challenges. When you’re following woodworking bench plans, there are several common pitfalls that can derail your project. By being mindful of these mistakes, you can save time and materials, ensuring a smoother building process. Here are some key things to watch out for:

Choosing the Wrong Plans

One significant mistake is selecting woodworking bench plans that don’t match your skill level. Each project varies in complexity and some may seem appealing but are better suited for advanced woodworkers. Be sure to evaluate your experience and choose plans that align with your abilities. If you’re a beginner, look for straightforward designs that clearly outline all steps.

Ignoring Material Recommendations

Woodworking plans typically include suggestions for materials. Ignoring these recommendations can lead to poor results. For instance, using a low-grade wood when the plans specify high-quality hardwood can impact durability and stability. Always follow the material guidelines to achieve the best outcome.

Not Gathering Tools Prior to Starting

Starting a woodworking project without the necessary tools can cause frustration. Before you dive in, take stock of the tools you need. A typical woodworking bench may require:

- Table saw

- Miter saw

- Drill

- Clamps

- Sanders

- Measuring tape

Having everything prepared will keep you on track and save you from interruptions mid-project.

Failure to Measure Accurately

Precision is crucial in woodworking. One of the most common errors arises from incorrect measurements. Always double-check your dimensions before cutting. It’s helpful to use a measuring tape and a square to ensure your marks are straight and accurate. A minor error in measurement can lead to discrepancies that may complicate the assembly process.

Rushing Through the Assembly

Patience is key in woodworking. Many beginners rush through the assembly phase, hoping to see results quickly. However, this can lead to mistakes. Instead, take your time to follow the steps outlined in your woodworking bench plans carefully. Remember, it’s better to spend extra time doing it right than to have to redo parts later.

Neglecting Safety Precautions

Safety should always be your top priority. Using power tools without proper safety measures can lead to accidents. Be sure to wear protective gear like goggles and a dust mask. Additionally, read the instructions for each tool you use, ensuring you operate them correctly. Safety is fundamental and should never be overlooked.

Not Finishing or Sealing the Wood

After constructing your woodworking bench, many tend to skip the surface finishing step. Sealing or applying a finish not only enhances the appearance of the wood but also protects it from wear and tear. Consider using stains, varnishes, or lagging to enhance durability and finish. It’s a simple step that makes a big difference.

Helpful Resources

For those looking for high-quality woodworking bench plans, consider checking out these resources:

By avoiding these common mistakes when following woodworking bench plans, you can enhance your building experience and create a beautiful, functional piece. Remember that good preparation and careful attention to detail can significantly improve your woodworking projects.

Conclusion

Building the perfect woodworking bench is not only about selecting the right plans; it’s also about understanding your needs and the space you have available. By taking the time to explore essential features—like height, material, and storage options—you can create a workspace that truly enhances your woodworking experience.

Customizing your bench design can significantly improve your workflow and comfort, allowing the bench to cater specifically to your projects. Whether you choose a sturdy cabinet style, a versatile folding design, or a simple traditional bench, each type has unique advantages that can suit different woodworking styles and requirements.

As you embark on this project, remember that effective construction is guided not only by accurate woodworking bench plans but also by patience and precision. Avoid common pitfalls by carefully following your chosen plans, paying attention to detail, and adapting your design to your skill level.

With the right approach, your woodworking bench can become a hub of creativity and productivity, empowering you to turn your ideas into tangible products. Prioritize features that matter most to you, embrace customization, and learn from others’ mistakes to ensure that your bench-building journey is both enjoyable and successful. Whether you’re just starting or looking to upgrade your workspace, the right woodworking bench can make all the difference in your craft. Dive in with confidence and watch your woodworking skills flourish!