ATTENTION: World's Largest Collection of 16,000 Woodworking Plans!

Stop struggling with incomplete plans that waste your time and money!

Step-by-step instructions that make woodworking super easy, even for beginners

Detailed schematics, cutting lists, and materials lists for every project

Get new plans monthly for life - no recurring fees or hidden costs

Request custom plans for your unique projects at no extra charge

Get 4 valuable bonuses including woodworking guides and business tips

GET INSTANT ACCESS NOW!

ATTENTION: World's Largest Collection of 16,000 Woodworking Plans!

Stop struggling with incomplete plans that waste your time and money!

Step-by-step instructions that make woodworking super easy, even for beginners

Detailed schematics, cutting lists, and materials lists for every project

Get new plans monthly for life - no recurring fees or hidden costs

Request custom plans for your unique projects at no extra charge

Get 4 valuable bonuses including woodworking guides and business tips

GET INSTANT ACCESS NOW!

Choosing the right circular saw blades is essential for achieving optimal results in your woodworking and construction projects. With various types available, selecting the proper blade can significantly affect your cutting efficiency, finish quality, and overall safety. Whether you’re a professional or a DIY enthusiast, understanding how to pick the best blade for your needs is vital.

Nominally, circular saw blades come in multiple types, material compositions, and tooth configurations. Each aspect influences the performance of the blade in different applications. Let’s dive into some critical factors to consider when choosing a circular saw blade.

Types of Circular Saw Blades

There are several types of circular saw blades available, each designed for specific tasks. Here’s a quick breakdown:

- General Purpose Blades: These blades are versatile and can cut through various materials, including wood, plywood, and laminate. They typically feature alternating top bevel teeth for a cleaner cut.

- Crosscut Blades: Designed specifically for making crosscuts in wood, these blades have more teeth (often 60 to 80) for a smoother finish.

- Ripping Blades: Ideal for ripping down boards, these blades have fewer teeth (24 to 30) to speed up the cut and reduce binding.

- Masonry Blades: Used for cutting brick, concrete, or tile, masonry blades feature a diamond-infused edge.

- Specialty Blades: These include blades for cutting metal and for specific applications like foam or plastic materials.

Materials and Coatings

The material of the blade is another crucial factor. High-Carbon Steel (HCS) blades are durable but less resistant to heat. Carbide-Tipped blades are favored for their longevity and can handle a variety of materials. Additionally, some blades come with coatings like:

- Teflon Coating: Reduces friction and keeps the blade clean.

- Anti-Kickback Design: Prevents the blade from binding in the material being cut.

Tooth Configuration

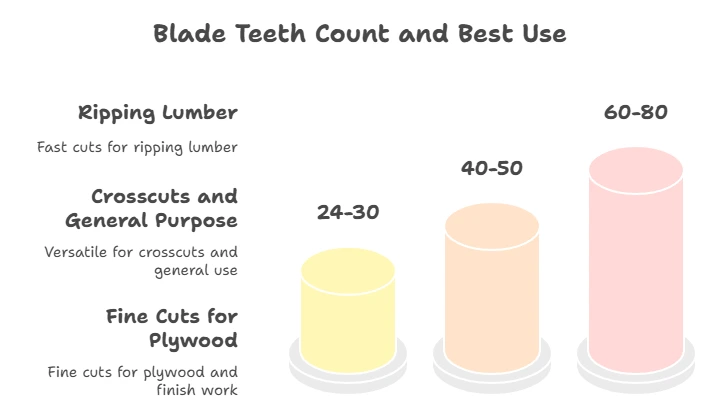

The number of teeth on a blade influences how the cut will be made and the finish it will provide:

| Teeth Count | Best Use |

|---|---|

| 24-30 | Ripping lumber and fast cuts |

| 40-50 | Crosscuts and general-purpose cutting |

| 60-80 | Fine cuts for plywood and finish work |

Choosing the Right Diameter

Circular saw blades come in various diameters, typically ranging from 4 inches to 12 inches. The diameter you choose depends on your circular saw and the type of cuts you intend to make. Here’s a guideline:

- 7-1/4 inch: Common for most standard circular saws, suitable for general construction tasks.

- 10 inch: Often used in table saws and miter saws for woodworking.

Maintaining Your Blades

To extend the life of your circular saw blades, proper maintenance is essential. Here are a few tips:

- Keep your blades clean by removing pitch and debris after each use.

- Store blades in a protective case to prevent damage.

- Sharpen blades regularly, especially if you use them frequently.

Now that you have a better understanding of the various factors to consider when selecting circular saw blades, it’s essential to put this knowledge into practice. Visit Wood Magazine for more tips on maintenance and blade selection.

Moreover, ensure you understand the safety measures required when using a circular saw. Always wear appropriate safety gear, including eye protection and a dust mask. This will keep you safe as you tackle your projects with the right tools.

Choosing the right circular saw blades can greatly impact the outcome of your projects, whether you’re making complex cuts or simple straight lines. Take the time to research and invest in the best blades for your specific needs. Your work will not only look better but also be safer and more efficient. For more insightful information, check out Popular Mechanics.

Understanding the Different Types of Circular Saw Blades

Circular saw blades are essential tools for both professionals and hobbyists in woodworking, metalworking, and construction. Understanding the various types of circular saw blades available can help you choose the right blade for your specific cutting task. Each type is designed for particular materials, cutting methods, and efficiency levels. Let’s explore the different types of circular saw blades, their applications, and how to select the one that fits your needs.

When exploring circular saw blades, it’s important to consider the following types:

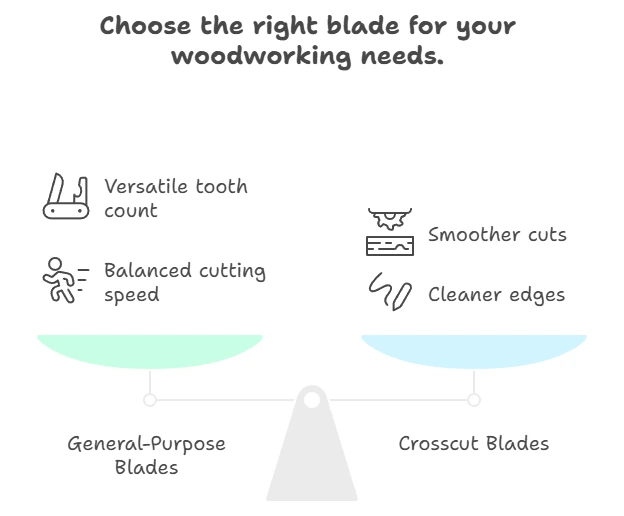

- General-Purpose Blades: These blades are versatile and can handle a variety of materials, including wood, plywood, and some composite materials. They typically have 24 to 40 teeth, making them suitable for rough cuts as well as smoother finishes.

- Crosscut Blades: Designed for cutting across the grain of wood, crosscut blades have more teeth (usually 60 to 80) than general-purpose blades. This results in smoother cuts and cleaner edges, making them ideal for finish work.

- Rip Blades: These blades are tailored for ripping wood along the grain. With fewer teeth (around 24 to 30), they cut quickly and aggressively, allowing for faster work during rough cutting of lumber.

- Combination Blades: As the name suggests, combination blades offer a mix of features that allow for both ripping and crosscutting. With around 40 to 50 teeth, they provide a good balance between efficiency and quality, making them a popular choice for general woodworking tasks.

- Specialty Blades: This category includes blades designed for specific tasks or materials. For example, there are:

- Wood Cutting Blades: Specifically designed to cut hardwood, softwood, and composites.

- Metal Cutting Blades: Made from high-speed steel or carbide-tipped for cutting through metal like aluminum and steel.

- Diamond Blades: Ideal for cutting hard materials like tile, concrete, and masonry, featuring diamond crystals embedded in the blade.

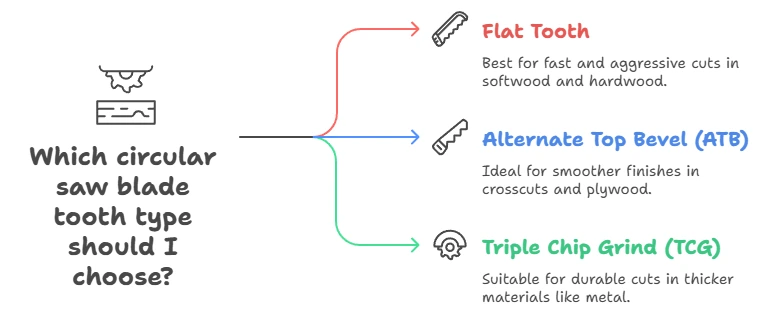

Choosing the right circular saw blade also involves understanding tooth geometry, which affects the blade’s performance:

| Tooth Type | Description | Best for |

|---|---|---|

| Flat Tooth | Creates a fast and aggressive cut. | Rip cuts in softwood and hardwood. |

| Alternate Top Bevel (ATB) | Teeth alternate in a bevel to create a smoother finish. | Crosscuts and plywood. |

| Triple Chip Grind (TCG) | Combines flat and beveled teeth for durability. | Ripping and cutting thicker materials like metal. |

Another factor to consider is the blade material. Most blades are made from:

- High-Speed Steel (HSS): Offers good wear resistance but may dull faster than carbide.

- Carbide-Tipped Blades: These blades have a higher initial cost but stay sharp longer, making them suitable for heavy use.

- Diamond Blades: Known for extreme durability, they are more expensive but essential for cutting hard materials.

Furthermore, understanding blade diameter is essential. Circular saw blades range from 4 inches to 12 inches and beyond. The diameter affects the depth of the cut you can achieve. For example:

- A 7¼-inch blade is common for most standard circular saws and can cut 2× lumber in one pass.

- A 10-inch blade can cut deeper and is often used for larger, more powerful saws.

To get the most out of your circular saw blade, remember to consider the material you’ll be cutting, the type of cut you need, and the machine you’ll be using. Regularly cleaning and maintaining your blades can help extend their lifespan and maintain their cutting efficiency. You can find replacement blades and maintenance tips on websites like Toolbarn or Amazon.

By understanding the nuances of circular saw blades, you’ll be better equipped to make informed decisions for your wood and metal projects. This knowledge not only saves time but enhances the quality of your work. So, dive into your project with the right blade, and enjoy the smooth, precise cuts that come with it!

Maintenance Tips to Extend the Life of Your Circular Saw Blades

Taking care of your circular saw blades is essential for both safety and performance. With proper maintenance, you can extend their life significantly, ensuring clean cuts and better overall results. Here are some effective tips to keep your circular saw blades in top condition.

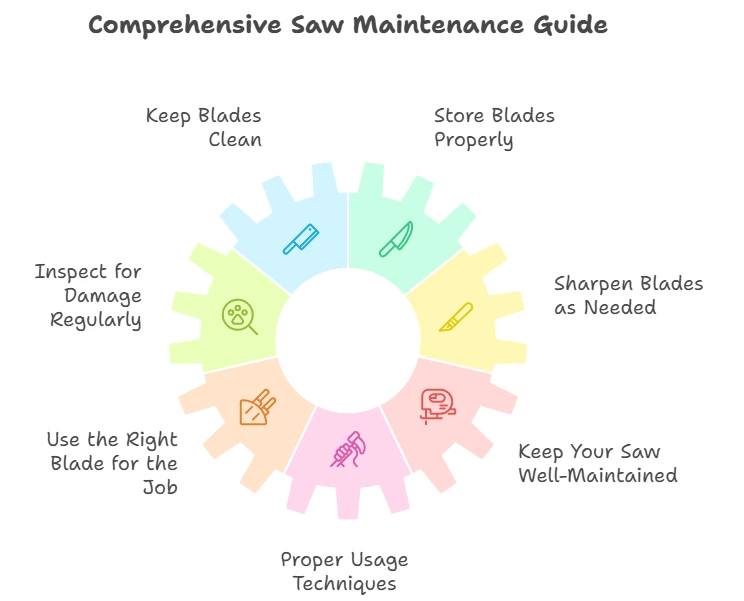

Keep Blades Clean

Debris such as sawdust and resin can build up on your blades, affecting performance. To clean your circular saw blades:

- Use a soft brush or cloth to wipe the blades after each use.

- For tougher build-up, soak the blades in a solution of warm water and a mild detergent for about 15 minutes.

- Rinse and dry thoroughly to prevent rust.

Store Blades Properly

Correct storage can also enhance the lifespan of your blades. Consider the following options:

- Store blades in a protective case or sheath to avoid physical damage.

- Keep them in a dry place to prevent rust.

- Avoid stacking blades directly on top of each other; use dividers instead.

Inspect for Damage Regularly

Frequent inspections will help you catch potential issues before they worsen. Here’s what to look for:

- Check for any bent teeth or dull edges.

- Look for cracks or chips that can lead to accidents.

- Ensure that the mounting holes are not worn out.

Sharpen Blades as Needed

Keeping your saw blades sharp is crucial for achieving clean cuts. Follow these steps to maintain sharpness:

- Use a sharpening stone or file to sharpen the blades manually.

- Consider investing in a blade sharpener if you’re a frequent user.

- For professional results, you might opt to take your blades to a sharpening service.

Use the Right Blade for the Job

Using the correct blade can make all the difference in both performance and longevity. Here are a few pointers:

- Choose a blade specifically designed for the material you are cutting—wood, metal, or masonry.

- Ensure the blade size matches your circular saw specifications.

- Utilize specialty blades for specific applications, such as a fine-tooth blade for smooth finishes.

Keep Your Saw Well-Maintained

Aside from caring for the blades, maintaining the saw itself is important. Consider these tips:

- Regularly check the alignment of your saw to minimize blade wear.

- Lubricate moving parts according to the manufacturer’s guidelines.

- Replace worn belts or cords promptly to ensure safety.

Proper Usage Techniques

Your cutting techniques can also impact the lifespan of your circular saw blades. Apply these practices:

- Let the blade do the cutting without excessive pressure.

- Move at a steady speed for smooth cuts without overheating the blade.

- Always use a guide for straight cuts to avoid binding.

Taking small steps to maintain your circular saw blades ultimately saves you time and money. Proper maintenance means you’ll achieve better results and keep your equipment in top shape for years. For more information and professional insights, check out Toolbarn and MaxTool, both offer a wide selection of circular saw blades and maintenance tools.

| Maintenance Task | Frequency |

|---|---|

| Clean Blades | After Each Use |

| Inspect for Damage | Weekly |

| Sharpen Blades | As Needed |

| Check Saw Alignment | Every Month |

By implementing these maintenance tips, you ensure that your circular saw blades operate efficiently, ultimately leading to safer and more enjoyable woodworking or construction tasks.

Common Mistakes to Avoid When Using Circular Saw Blades

Circular saw blades are essential tools for woodworkers, carpenters, and DIY enthusiasts. However, using them incorrectly can lead to poor results and safety hazards. To ensure you maximize their performance while minimizing risks, it’s important to know the common mistakes you should avoid when using circular saw blades.

Choosing the Wrong Type of Blade

One common mistake is using the wrong type of blade for the material you are cutting. Circular saw blades are designed for specific tasks. For example:

- Crosscut Blades: Ideal for cutting across the grain of the wood.

- Rip Blades: Designed for cutting along the grain.

- Combo Blades: Versatile for both crosscutting and ripping.

- Metal Cutting Blades: Best for metals and harder materials.

Using the correct blade can significantly enhance cutting efficiency and reduce wear and tear on your tool.

Neglecting Blade Maintenance

Another frequent mistake is overlooking the maintenance of your circular saw blades. Regularly check for the following:

- Sharpness: Dull blades increase cutting time and lead to burn marks.

- Cleaning: Remove sawdust and resin buildup to maintain cutting performance.

- Alignment: Ensure the blade is properly aligned to prevent binding.

Proper maintenance not only extends the blade’s life but also improves the quality of your cuts.

Improper Setup and Adjustments

Setting up your circular saw incorrectly can compromise safety and efficiency. Follow these essential tips:

- Always ensure the blade guard is functional and in place.

- Confirm that the blade is secured tightly and spins freely.

- Adjust the cutting depth appropriately; it should be just enough to cut through the material.

Ineffective Cutting Technique

Your cutting technique plays a crucial role in the effectiveness of your circular saw. Here are a few reminders:

- Always let the saw reach full speed before making contact with the material.

- Use even, steady pressure while cutting, avoiding force that can stress the saw and blade.

- Never push the saw too quickly; let the blade do the work to avoid overheating.

Overlooking Safety Precautions

Ignoring safety precautions is a serious mistake that can result in accidents. Here are essential safety tips:

- Wear appropriate personal protective equipment (PPE), such as safety glasses and hearing protection.

- Keep your workspace organized to reduce trip hazards.

- Disconnect the power source when changing blades or making adjustments.

Using Dull or Damaged Blades

Using a dull or damaged blade can worsen the quality of your cuts and increase the risk of kickback. Always inspect your blades for:

- Chips or cracks, which can create unstable cuts.

- Worn teeth, which can cause uneven cuts.

- Rust or corrosion, leading to decreased efficiency.

Not Following Manufacturer Guidelines

Each circular saw and blade manufacturer provides specific guidelines for their products. Always take time to read these instructions. This could include:

- Recommended RPM for specific blades.

- Proper installation techniques.

- Maintenance tips to prolong the lifespan of both the saw and blade.

By being aware of these common mistakes and taking the necessary precautions, you can greatly enhance the performance of your circular saw blades and ensure a safer cutting experience. For further advice and product recommendations, don’t hesitate to visit Toolmonger and Popular Mechanics.

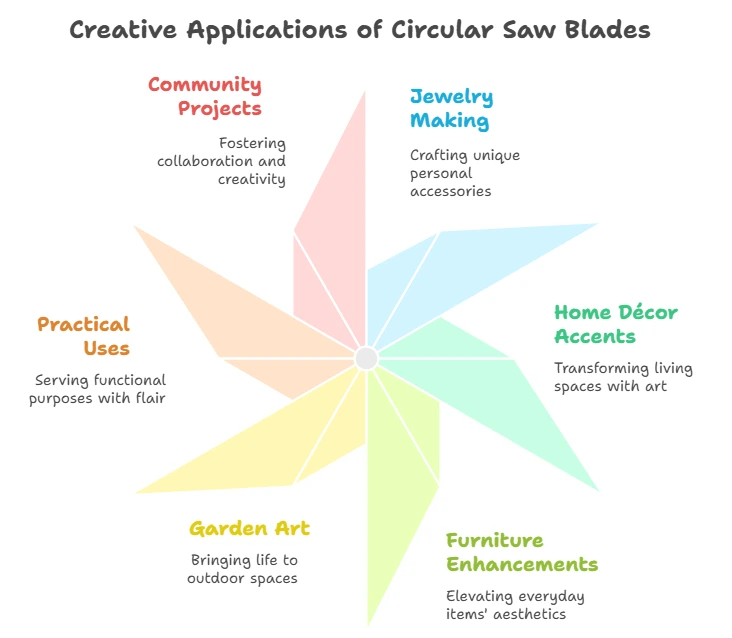

Innovative Uses for Circular Saw Blades in Crafting and DIY Projects

Circular saw blades are not just tools for cutting wood; they can also be the backbone of innovative crafting and DIY projects. If you have some old blades lying around, don’t throw them away. Instead, consider these creative uses that can transform them into unique items while adding an artistic flair to your space.

Jewelry Making

Old circular saw blades can become stunning jewelry pieces. Their unique textures and metal surfaces can be transformed into necklaces, bracelets, or earrings. Here’s how you can get started:

- Safety First: Always wear safety gloves and goggles when handling blades.

- Design: Sketch your design on the blade’s surface with a permanent marker.

- Cutting: Use a metal saw to carefully cut out your shapes.

- Sanding: Sand the edges to eliminate sharp spots and create a smooth finish.

- Assembly: Attach the pieces using jump rings and chains to create a unique jewelry line.

Home Décor Accents

Integrating circular saw blades into home décor can result in eye-catching pieces. Here are some ideas:

- Wall Art: Create a gallery wall by hanging different size blades in a pattern. Paint them in colors that match your décor for added visual interest.

- Mirrors: Attach blades around a round mirror to form an industrial-style frame. This can be a focal point in your living space.

- Table Centerpieces: Combine a circular saw blade with wood or glass bases to design a unique centerpiece for dining tables.

Furniture Enhancements

Transform your furniture by incorporating circular saw blades into your designs:

- Table Legs: Attach blades vertically as artistic legs for a coffee table. Secure them well for safety and stability.

- Cabinet Handles: Use smaller blades as handles on cabinets or drawers, giving them a rustic appeal.

Garden Art

For gardening enthusiasts, circular saw blades can add unique accents to outdoor spaces. Consider the following:

- Garden Stakes: Use blades to create stakes that can be adorned with stakes or plant markers. A protective coat of paint can prevent rust.

- Sculptures: Combine blades with other materials like wood or metal to create sculptures that can withstand outdoor conditions.

Practical Uses

Circular saw blades are not only good for decoration but can also be repurposed for practical applications:

- Sharpening Tool: With proper care, blades can be sharpened and used for cutting through tougher materials such as masonry or metal.

- Slice and Dice: If you’re looking to build homemade cutting tools, the sharp edges can be utilized in custom knives or utility tools for DIY projects.

Community Projects

Engaging in community arts and crafts can benefit from circular saw blades. Organize a workshop to show others how to repurpose these tools creatively. Sharing knowledge and resources can inspire others and potentially lead to collaborative projects.

As you explore these innovative uses for circular saw blades, remember to prioritize safety and creativity. For more inspiration, check out resources such as Instructables and Make: Magazine for DIY projects that cater to various skill levels.

Next time you come across a circular saw blade, instead of discarding it, think of the endless possibilities. Whether you’re crafting jewelry, enhancing your home décor, or getting creative in the garden, these blades can redefine how you approach crafting and DIY projects.

Conclusion

Selecting the right circular saw blades is crucial for achieving the best results in your projects. By understanding the various types of blades available, you can make informed decisions that cater specifically to your cutting needs, whether you’re using them for wood, metal, or other materials. Each blade has its own unique features that enhance performance, making it essential to match them with the tasks at hand.

Regular maintenance is equally important for prolonging the lifespan of your circular saw blades. Simple cleaning and proper storage can go a long way in keeping them sharp and effective for longer periods, saving you time and money down the line. Being mindful of common mistakes—like using the wrong blade or applying excessive pressure—can lead to safer and more efficient cutting experiences.

Circular saw blades are not just for typical construction projects. They can be transformed into innovative tools for crafting and DIY endeavors, opening up a world of creative possibilities. You might discover unexpected ways to utilize your blades, enhancing both your skills and the enjoyment you find in your projects.

Understanding, maintaining, and creatively using your circular saw blades empowers you to work smarter and achieve professional-quality results at home. With the right knowledge and care, you can fully harness the potential of these versatile tools for all your cutting needs, leading to more successful, enjoyable projects.