Have you ever run your hand across a piece of furniture you crafted yourself and thought, “I could sell this”? You’re not alone. With the surge in appreciation for handmade goods and the growing accessibility of online marketplaces, turning your woodworking hobby into a home-based business is more feasible than ever.

But can you really run a successful woodworking business from your home? Let’s talk about it—not as some distant dream, but as the practical possibility it actually is.

The Home Workshop Reality

I remember chatting with Miguel, a cabinet maker from Portland who started in his one-car garage. “Everyone told me I needed a commercial space,” he laughed. “Five years later, I’m still working from home and making six figures.”

Miguel isn’t an anomaly. The home-based woodworking model works for many, but it requires smart planning. Let’s break down what you need to consider:

Space Requirements: Thinking Beyond Square Footage

Your available space dictates what you can realistically produce. A coffee table business needs different accommodations than a custom cabinetry operation.

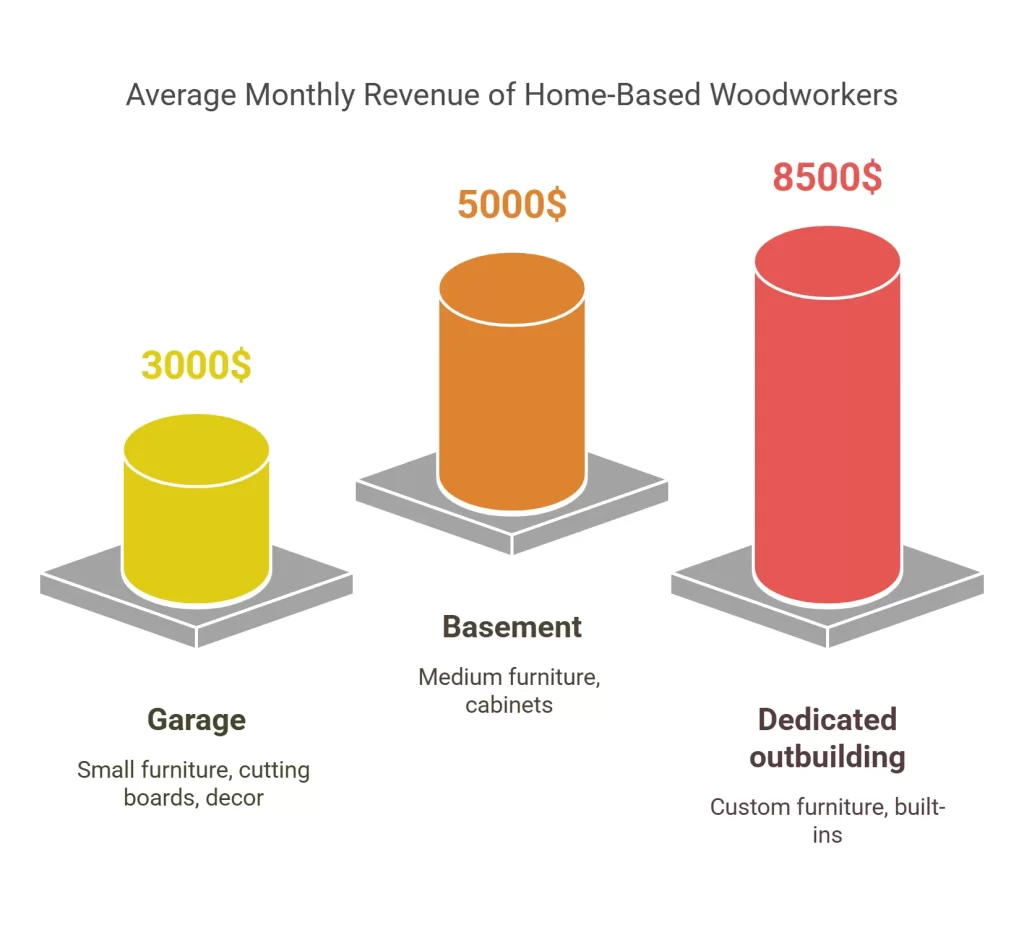

According to a survey by the Woodworking Network, successful home-based woodworkers typically work within these spaces:

| Workshop Size | Typical Products | Average Monthly Revenue |

|---|---|---|

| Garage (1-2 car) | Small furniture, cutting boards, decor | $2,000-$4,000 |

| Basement (500+ sq ft) | Medium furniture, cabinets | $3,500-$7,000 |

| Dedicated outbuilding | Custom furniture, built-ins | $5,000-$12,000+ |

But square footage isn’t the only consideration. You’ll need to think about:

- Ceiling height: Can you stand a bookshelf upright?

- Power capacity: Will your home’s electrical system support commercial tools?

- Sound insulation: Will your router wake the neighbors (or your sleeping baby)?

- Dust management: Can you keep sawdust from infiltrating your living space?

Legal Considerations: Yes, They Matter

Before you start selling those Adirondack chairs, you need to navigate some red tape.

Zoning Laws

Many residential areas have restrictions on home-based businesses, especially those involving manufacturing. Check your local zoning ordinances to ensure woodworking businesses are permitted in your area.

Some neighborhoods have specific restrictions on:

- Noise levels (those power tools can be loud!)

- Hours of operation

- Customer visits to your property

- Visible inventory or equipment

Business Structure and Licensing

You’ll need to decide on a business structure (sole proprietorship, LLC, etc.) and obtain the necessary licenses and permits. This typically includes:

- Business license

- Sales tax permit

- Home occupation permit

- Employer Identification Number (if applicable)

Insurance Considerations

Your homeowner’s insurance likely won’t cover your business activities. You’ll need:

- General liability insurance: Protects against claims of property damage or injury

- Product liability insurance: Coverage for issues with products you’ve made and sold

- Business property insurance: Covers your tools and invento

The Financial Picture: Making the Numbers Work

Let’s talk money. Running a woodworking business from home can be profitable, but understanding the financial landscape is crucial.

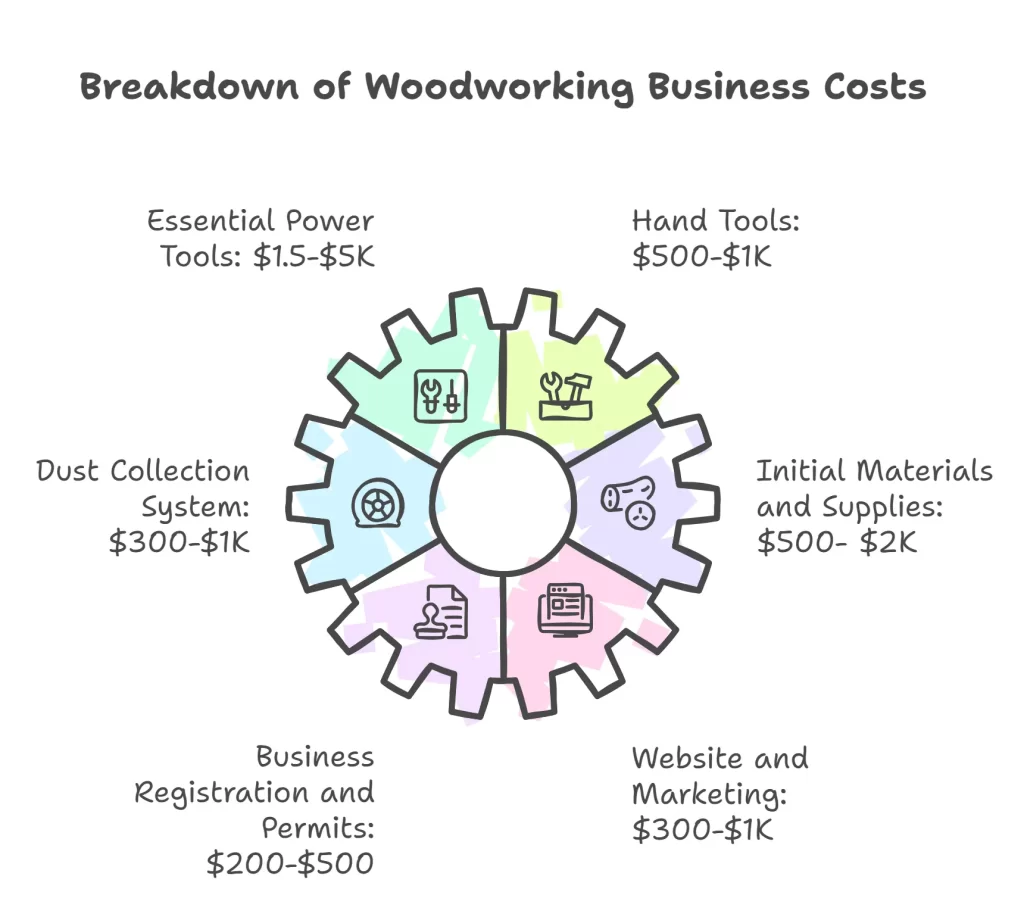

Startup Costs

Starting a home woodworking business typically costs between $2,500 and $10,000, depending on what tools you already own. Here’s a basic breakdown:

- Essential power tools: $1,500-$5,000

- Hand tools: $500-$1,000

- Dust collection system: $300-$1,00• Initial materials and supplies: $500-$2,000

- Business registration and permits: $200-$500

- Website and marketing: $300-$1,000

Profit Margins

Woodworking profit margins typically range from 25% to 50%, depending on your product niche and efficiency. Custom, high-end pieces command higher margins but take longer to produce.

Jim, a woodworker from Michigan who specializes in custom dining tables, shared: “I price my tables at 3x material costs plus $40 per hour. My margins improved dramatically once I found my niche and stopped trying to compete with mass-produced furniture prices.”

Finding Your Niche: The Key to Standing Out

The most successful home woodworkers aren’t trying to be everything to everyone. They’ve found specific niches where they excel.

Profitable niches for home-based woodworkers include:

- Cutting boards and kitchen items: High turnover, lower price points, great for beginners

- Custom furniture for specific needs: Think standing desks, nursery furniture, pet furniture

- Restoration and refinishing: Lower material costs, focus on craftsmansh

- Wooden toys: Appealing to parents seeking natural alternatives

- Specialized woodturning: Bowls, pens, and artistic pieces

Sara, who runs her turning business from a converted garden shed, told me: “When I focused exclusively on handcrafted wooden urns, my business took off. It’s a sensitive niche that people value craftsmanship in, and the items are small enough that I can produce them in my limited space.”

Marketing Your Woodworking Business

Even the most beautiful craftsmanship needs visibility to sell. Here’s how to market your home-based woodworking business effectively:

Building an Online Presence

- Professional website: Showcase your work with high-quality photography

- Social media strategy: Platforms like Instagram and Pinterest are visual and perfect for woodworking

- Content marketing: Share your process, tips, and the stories behind your pieces

Selling Platforms

Consider multiple sales channels:

- Etsy: Great for reaching craft-oriented customers

- Your own website: Higher profit margins but requires driving traffic

- Local craft fairs and markets: Build local clientele and get direct feedback

- Wholesale to local shops: Lower margins but consistent orders

Balancing Family Life and Business

Running a woodworking business from home means your work and personal life share the same space. This has advantages and challenges.

Mark, who builds custom furniture from his basement shop while raising two young children, shared his approach: “I only run power tools during school hours. Hand tool work I save for evenings. And I have a strict ‘dust-free’ routine before coming upstairs—changing clothes and using an air compressor to blow off.”

Consider creating:

- Dedicated business hours

- Physical boundaries between work and living spaces

- Systems for managing noise and du

- Clear communication with family members about expectations

Equipment and Tool Considerations

You don’t need every tool on day one. Start with the essentials and expand as your business grows.

Essential tools for most home woodworking businesses include:

- Table saw: The centerpiece of most woodworking shops

- Miter saw: For precise crosscuts

- Router: Versatile for edges, joinery, and decorative work

- Sander: Random orbital sanders save countless hours

- Basic hand tools: Chisels, planes, and measuring tools

- Dust collection system: Critical for health and home cleanliness

Advanced tools to consider as you grow:

- Jointer and planer: For preparing rough lumber

- Band saw: For curves and resawing

- Lathe: If turning is part of your business model

- CNC router: For precision, repeatability, and scaling production

Scaling Your Home-Based Woodworking Business

As your business grows, you’ll face decisions about scaling. Here are some approaches:

Within Your Home Space

- Efficiency improvements: Workflow optimization, jigs, and templates

- Product design refinement: Creating designs that maximize output while maintaining quality

- Hiring part-time help: Perhaps for finishing or assembly steps

- Batch production: Making multiple similar items at once

Beyond Your Home

When you outgrow your home workshop, consider:

- Renting production space: Keep business operations separate from home

- Outsourcing components: Having some parts made by others

- Collaborating with other craftspeople: Sharing larger j

- Creating digital products: Plans, courses, or consultation services

The Sustainability Angle: A Modern Selling Point

Sustainability is increasingly important to consumers. Home-based woodworking businesses are perfectly positioned to emphasize their sustainable practices:

- Local materials: Sourcing from nearby sawmills or urban tree removal services

- Minimal transportation: Lower carbon footprint than imported furniture

- Scrap utilization: Turning offcuts into smaller products

- Longevity: Creating pieces designed to last generations

Jack, who makes heirloom rocking chairs, notes: “I tell my customers that each chair sequests approximately 400 pounds of carbon dioxide over its lifetime. People love knowing their furniture purchase is actually helping the environment.”

Learning From Others: Community Support

The woodworking community is exceptionally supportive. Tap into:

- Local woodworking guilds: Networking and skill-sharing

- Online forums: Feedback and problem-solving

- Social media groups: Marketing opportunities and peer support

- Mentorship relationships: Learning from established woodworkers

Conclusion: Yes, You Can!

Running a successful woodworking business from home is absolutely achievable. It requires planning, dedication, and creativity, but the rewards extend beyond financial gain. There’s something deeply satisfying about turning raw wood into beautiful, functional objects that bring joy to others—all while working in your own space, on your own terms.

Whether you’re just contemplating this path or already have sawdust in your hair, remember that today’s most successful woodworkers all started with a single project and a vision. Your home workshop could be the birthplace of not just beautiful woodwork, but a sustainable business and lifestyle you love.

Now, I’d love to hear from you. Are you running a woodworking business from home, or thinking about starting one? What challenges or successes have you experienced? Share in the comments below!