When embarking on woodworking projects, selecting the right Woodworking Adhesives can significantly impact the outcome of your work. The right adhesive not only ensures the durability of your projects but also affects the aesthetic look and overall integrity of the final product. When you choose an adhesive, you want to consider several factors like the types of materials you are bonding, the environmental conditions, and the specific requirements of your project. Below is a comprehensive exploration of Woodworking Adhesives to help make your choice easier and more effective.

Types of Woodworking Adhesives

Understanding the various types of Woodworking Adhesives available can aid you in selecting the most appropriate one for your needs. Here are some popular kinds:

- PVA (Polyvinyl Acetate) Glue: This is a white or yellow adhesive known for its strong bond and ease of use. It’s ideal for indoor projects and works well with porous woods.

- Polyurethane Glue: This adhesive expands when it cures, making it suitable for gap-filling. It’s waterproof and best for outdoor projects.

- Epoxy: Epoxy resins provide a rigid bond and excellent gap-filling capabilities. They are effective for difficult bonding situations, including metal and plastic.

- Aliphatic Resin: Similar to PVA, this type of glue is often used in woodworking for its strong bond but dries clear, making it perfect for visible joints.

- Hot Melt Glue: Quick to set and easy to use, hot melt glue is great for temporary fixes and applications requiring instant bonding.

Factors to Consider When Choosing Woodworking Adhesives

Choosing the right adhesive goes beyond just picking a type; you need to match it with the specific needs of your project. Consider the following factors:

| Factor | Considerations |

|---|---|

| Material Type | Different adhesives bond better with specific materials. For example, PVA works well with wood, while epoxy can also bond metal. |

| Environmental Conditions | Is the project for indoors or outdoors? If it’s exposed to moisture, consider a waterproof adhesive like polyurethane. |

| Bonding Speed | Do you need an instant bond? Hot melt glue works quickly while PVA takes longer to set. |

| Application Method | Some adhesives are better for specific application methods, like brushes, sprays, or direct applications. |

Benefits of Using the Right Woodworking Adhesives

Using the proper adhesive can enhance both your efficiency and the quality of your work. Here are some benefits you may experience:

- Stronger Joints: The right adhesive creates a solid bond, which is essential for the strength of your projects.

- Improved Durability: Using the adhesive designed for your project’s environment can extend the lifespan of your woodwork.

- Better Aesthetics: Some adhesives dry clear or can be sanded to hide joints, making your work look more professional.

- Versatility: Understanding the range of adhesives allows you to tackle diverse projects effectively.

Tips for Applying Woodworking Adhesives

To maximize the performance of your chosen adhesive, keep these tips in mind:

- Always follow the manufacturer’s instructions for application and curing times.

- Prepare surfaces by cleaning and, if necessary, sanding them rough for improved bonding.

- Apply adhesive evenly and consider using clamps to hold pieces in place during curing.

- Test the adhesive on scraps to ensure compatibility with your materials.

The right Woodworking Adhesives can transform your project from average to outstanding. Whether you’re a novice or an experienced woodworker, understanding your adhesive options and their applications will undoubtedly elevate your work. For further information on Woodworking Adhesives and their applications, you might find valuable insights at Wood Magazine or Woodworkers Source. Making an informed choice will not only enhance the quality and longevity of your woodworking projects but also enhance your joy and satisfaction in creating something truly special.

Comparing Different Types of Woodworking Adhesives: Pros and Cons

When it comes to woodworking, choosing the right adhesive can significantly impact the strength and longevity of your projects. Different types of Woodworking Adhesives offer unique advantages and disadvantages, making it essential to understand their properties before making a selection. Below is a comparison of popular Woodworking Adhesives to help you make an informed choice.

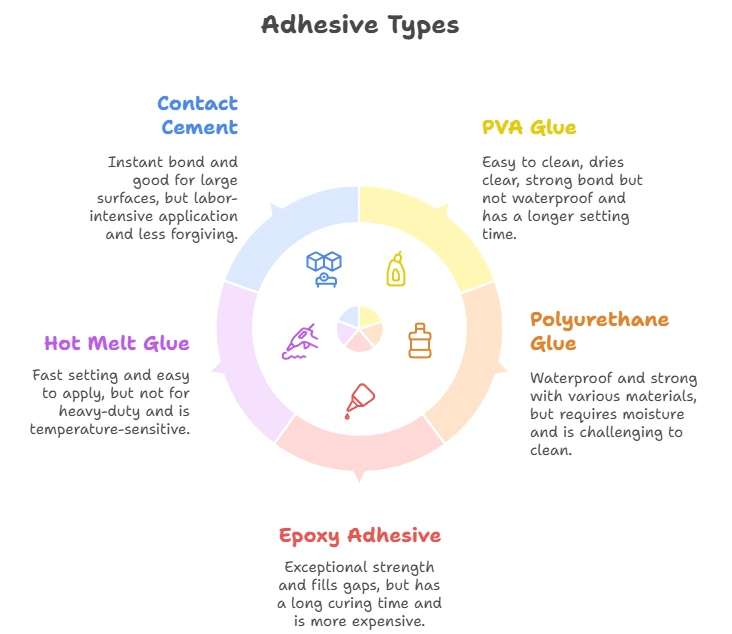

PVA Glue (Polyvinyl Acetate)

PVA glue is one of the most commonly used adhesives in woodworking. Known for its ease of use and versatility, it works well with many types of wood.

Pros:

- Easy to clean up with water when wet.

- Dries clear, making it ideal for visible joints.

- Creates a strong bond suitable for most indoor projects.

Cons:

- Not waterproof, which limits outdoor use.

- Setting time can be longer compared to other adhesives.

Polyurethane Glue

Polyurethane glue is a robust adhesive that expands as it cures, creating a powerful bond.

Pros:

- Waterproof, making it great for outdoor furniture.

- Strong bonds with various materials, including metal and plastic.

- Works well in extreme temperatures.

Cons:

- Requires moisture to cure, which can complicate the application.

- Cleanup can be challenging; it can create a mess if not handled correctly.

Epoxy Adhesive

Epoxy adhesives are two-part systems that provide exceptional strength and durability. They are suitable for various applications, including woodworking.

Pros:

- Excellent strength and resistance to heat, chemicals, and moisture.

- Ideal for use on non-porous surfaces.

- Can fill gaps, making it perfect for uneven edges.

Cons:

- Long curing time compared to other adhesives.

- Can be more expensive than other options.

Hot Melt Glue

Hot melt glue is a thermoplastic adhesive that melts when heated and hardens upon cooling. It’s used for quick-fix jobs and temporary bonding.

Pros:

- Fast setting time, making it ideal for quick repairs.

- Good for bonding lightweight materials.

- Easy to handle and apply.

Cons:

- Not suitable for heavy-duty applications.

- Temperature-sensitive; may weaken in extreme heat.

Contact Cement

Contact cement is a powerful adhesive that bonds on contact. It’s commonly used for laminating surfaces.

Pros:

- Creates an instant bond upon contact.

- Good for large surfaces, like countertops.

- Flexible once cured, allowing some movement without breaking.

Cons:

- Preparation and application can be labor-intensive.

- Less forgiving; misaligned pieces cannot be adjusted.

When selecting a Woodworking Adhesives, consider the specific needs of your project. Factors such as the types of wood being joined, whether the project will be exposed to moisture, and the required strength will influence your choice. Each adhesive has its own optimal use case, so understanding these aspects can help you achieve the best results. For further details on Woodworking Adhesives, check out resources on Wood Magazine or Popular Woodworking.

| Adhesive Type | Pros | Cons |

|---|---|---|

| PVA Glue | Easy to clean, dries clear, strong bond | Not waterproof, longer setting time |

| Polyurethane Glue | Waterproof, strong with various materials | Requires moisture, challenging cleanup |

| Epoxy Adhesive | Exceptional strength, fills gaps | Long curing time, more expensive |

| Hot Melt Glue | Fast setting, easy to apply | Not for heavy-duty, temperature-sensitive |

| Contact Cement | Instant bond, good for large surfaces | Labor-intensive application, less forgiving |

With so many options available, take the time to evaluate your needs before choosing a Woodworking Adhesives. Knowing the pros and cons of each type will ensure that your projects remain durable and successful.

Tips for Applying Woodworking Adhesives Effectively

Working with Woodworking Adhesives can be both rewarding and frustrating. The right adhesive can strengthen your projects and enhance their flair. Here are essential tips to apply Woodworking Adhesives effectively and maximize your results.

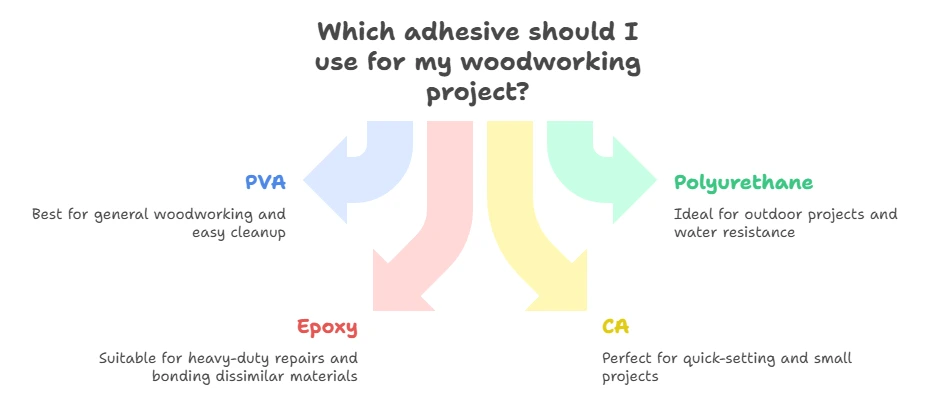

Understand Different Types of Woodworking Adhesives

Before you start, it’s crucial to know the various types of adhesives available. Here’s a quick overview:

| Type of Adhesive | Description | Best For |

|---|---|---|

| PVA (Polyvinyl Acetate) | Common white glue, easy to clean with water | General woodworking and furniture making |

| Polyurethane | Water-resistant, expands when curing | Outdoor projects and wooden flooring |

| Epoxy | Two-part adhesive, very strong and durable | Heavy-duty repairs and bonding dissimilar materials |

| CA (Cyanoacrylate) | Quick-setting adhesive, ideal for small projects | Model making and fast repairs |

Selecting the right adhesive based on your project is the first step toward effective application. Research each type before diving into your woodworking tasks.

Prepare Your Workspace

To apply Woodworking Adhesives efficiently, start by preparing a clean and organized workspace. Here are some key points:

- Ensure that your work surface is flat and free of dust and debris.

- Gather all your materials and tools, including clamps, a brush for spreading glue, and cleanup rags.

- Keep safety gear, like gloves and goggles, handy, as some adhesives can be toxic.

Surface Preparation

Proper surface preparation is crucial for adhesion. Here’s how to ensure optimal adhesion:

- Sand the Wood: Use sandpaper to roughen the surfaces that will be glued. This increases the bonding area.

- Clean the Surface: Remove any dust, grease, or oil. A clean surface allows adhesives to bond better.

Applying the Adhesive

When you’re ready to apply the adhesive, follow these guidelines:

- Use the Right Amount: Apply a thin, even layer. Excess adhesive can create a mess and may weaken the bond.

- Spread Evenly: If using PVA or epoxy, use a brush or roller for an even spread.

- Join the Pieces: Immediately after applying adhesive, join the pieces together. Make sure to align them properly.

Clamping Your Work

Clamping is essential for a strong bond. Here’s what you need to know:

- Choose the Right Clamp: Select a clamp suitable for your project size. F-style clamps are commonly used.

- Apply Even Pressure: Ensure even pressure across the joint to avoid gaps. Too much pressure can squeeze out too much adhesive.

- Check for Excess Glue: Wipe away any excess adhesive that seeps out before it dries. This will make finishing easier later.

Allow for Proper Curing Time

Let the adhesive cure according to the manufacturer’s instructions. Not allowing enough time can lead to weak bonds. Typically, PVA glues require 24 hours to cure fully, while polyurethanes may take longer.

Post-Application Tips

Once the adhesive has cured, you can proceed with your project. Here are additional tips:

- Check the Bond: Test the strength of the bond before applying any weight to the project.

- Finishing Touches: Sand down any dried adhesive remnants for a smooth finish.

- Store Properly: Keep leftover adhesive in a cool, dry place, tightly sealed, to preserve its effectiveness.

For more detailed guidance on Woodworking Adhesives, consider visiting resources like Wood Magazine or Woodworking Trade.

By following these tips, you can apply Woodworking Adhesives effectively and elevate the quality of your projects. A little preparation goes a long way in achieving strong and durable wood bonds.

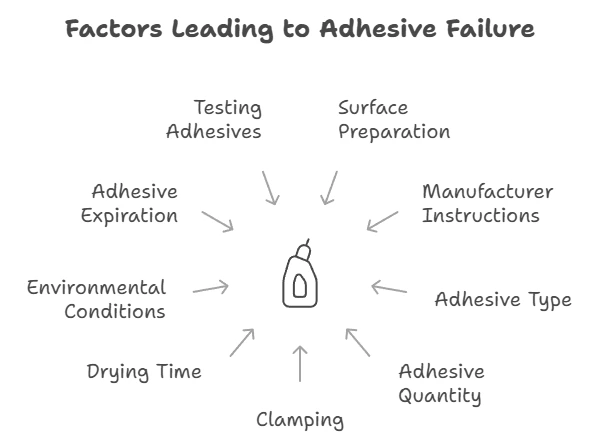

Common Mistakes to Avoid When Using Woodworking Adhesives

When working with Woodworking Adhesives, a few common mistakes can lead to less-than-ideal results. Understanding these pitfalls can help you achieve successful bonds in your projects. Here are some important points to consider to make sure your woodworking endeavors are successful.

Not Preparing the Surface Properly

One of the biggest mistakes you can make when using Woodworking Adhesives is failing to prepare the surfaces you intend to bond. For the best adhesion, surfaces need to be clean, dry, and free of dust or oils. Use sandpaper to lightly scuff up the areas where glue will be applied, which increases the surface area for adhesion.

Ignoring Manufacturer Instructions

Each Woodworking Adhesives has specific instructions from the manufacturer regarding usage. Ignoring these guidelines can lead to problems such as improper bonding strength or delayed drying times. Be sure to read and understand the directions before starting your project to ensure optimal results.

Using the Wrong Type of Adhesive

Not all adhesives are created equal. Using the wrong type for your project can compromise the bond. For example, PVA (polyvinyl acetate) glue is great for indoor projects but may not withstand outdoor conditions. Here’s a quick look at some common types of Woodworking Adhesives:

| Type | Best Used For |

|---|---|

| PVA Glue | General woodworking, furniture, indoor projects |

| Polyurethane Glue | Outdoor projects, waterproof applications |

| Epoxy Resin | High-strength bonds, filling gaps |

| Applying Too Much or Too Little Adhesive | Can weaken the bond; use proper amount for best results |

Applying Too Much or Too Little Adhesive

Finding the right amount of adhesive can be tricky. Applying too much adhesive may cause squeezing out, which can create a mess and weaken the bond. Conversely, using too little can lead to insufficient adhesion. Aim for a thin, even layer when applying the adhesive for the best results.

Neglecting to Clamp Your Pieces

After applying adhesive, it’s essential to clamp the pieces together securely. Failing to do so can result in weak bonds or misaligned joints. Depending on the project, clamping times may vary, so make sure you understand the requirements for the adhesive you’re using. Wood Magazine provides great insights on this topic.

Not Allowing Sufficient Drying Time

Rushing the drying process can lead to catastrophic failures down the line. Make sure you allow the adhesive to cure fully before putting the pieces under stress. This timeline can vary based on the adhesive used, environmental conditions, and the materials being bonded. Always refer to the manufacturer’s recommendations for drying times.

Overlooking Temperature and Humidity

Environmental conditions play a crucial role in how well adhesives perform. Extreme temperatures or high humidity can affect how adhesives bond. Try to work in a stable environment or consider using a dehumidifier or heater when necessary. When working in different climates, understanding how your chosen adhesive will react can lead to better outcomes.

Using Expired Adhesives

Adhesives come with shelf lives, and using expired products can result in weak bonds. Always check the expiration date before beginning new projects. Even if the adhesive seems fine, its effectiveness might be compromised. Invest in fresh supplies to ensure the best performance.

Failing to Test Different Adhesives

Every project is unique, and the materials you’re using may have different bonding needs. Consider testing different adhesives on sample pieces before committing to your final design. This approach can save you time and materials, ensuring your final project is a success.

Woodworking Adhesives are essential tools in your crafting toolkit, but avoiding common mistakes is key to ensuring solid results. With careful preparation and attention to detail, you can master the art of bonding! For more in-depth information about Woodworking Adhesives, visit Woodworking Network.

Innovative Techniques to Enhance Bonding with Woodworking Adhesives

Effective bonding is key in woodworking projects, and utilizing the appropriate adhesives can make a huge difference. Woodworking Adhesives have come a long way from traditional options. Today’s modern adhesives offer innovative solutions that enhance bonding and promote durability. If you’re looking to elevate your woodworking game, consider these advanced techniques to improve adhesion.

Select the Right Adhesive for Your Project

The first step in enhancing bonding in woodworking is choosing the right adhesive. Each type of adhesive has its unique properties, making it suitable for specific applications. Here’s a quick overview of some common Woodworking Adhesives:

- PVA (Polyvinyl Acetate): Commonly used for furniture and cabinetry, PVA is easy to apply and provides a strong bond.

- Epoxy: This two-part adhesive is ideal for bonding wood to wood or wood to other materials like metal or plastic. It’s waterproof and offers excellent strength.

- Polyurethane Glue: This glue expands as it cures, filling gaps effectively and creating a robust bond. It’s perfect for exterior projects due to its waterproof properties.

- Hot Glue: While not as strong as other types, hot glue is quick-drying and works well for temporary placements or lightweight projects.

Surface Preparation Matters

For optimal bonding, surface preparation is crucial. The surfaces you intend to bond must be clean, dry, and free from contaminants. Consider these steps for effective preparation:

- Sand the Surface: Use sandpaper to create a rough surface that enhances adhesive grip.

- Clean Thoroughly: Remove sawdust, grease, and other residues using a damp cloth or a mild detergent.

- Dry Completely: Ensure surfaces are completely dry before applying adhesive. Moisture can weaken the bond.

Utilizing Clamping Techniques

Clamping your pieces helps in achieving an even distribution of pressure, allowing for better adhesion. Here are some effective clamping techniques:

- Parallel Clamps: Ideal for larger panels, these clamps ensure uniform pressure across the entire surface.

- Hand Screws: Great for holding awkward shapes, hand screws can adjust to various angles and widths.

- Pipe Clamps: Useful for larger projects, these can adapt for various lengths and hold significant pressure.

Temperature and Humidity Control

The environment in which you work can greatly affect adhesive performance. Temperatures between 70°F and 90°F are generally ideal for most Woodworking Adhesives. High humidity can additionally impact the curing process. Consider these tips:

- Work in a climate-controlled environment when possible.

- Avoid using adhesives on rainy or overly humid days.

Experimenting with Adhesive Combinations

Sometimes, enhancing bonding might require combining different adhesive types. For instance, using epoxy for structural integrity, followed by a PVA for finishing touches, can yield excellent results. Always test combinations on scrap materials to see how they perform.

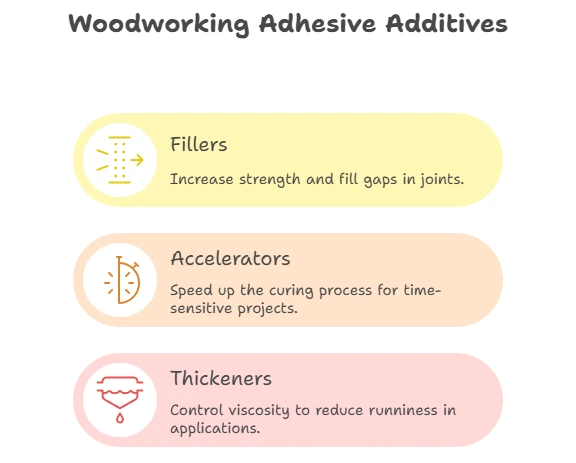

Choosing Additives and Accelerators

Additives can enhance your Woodworking Adhesives. For example, you can use accelerators with epoxy to speed up curing time or incorporate fillers for added strength. Here are some commonly used additives:

| Additive | Benefits |

|---|---|

| Fillers | Increase strength and fill gaps in joints. |

| Accelerators | Speed up the curing process for time-sensitive projects. |

| Thickeners | Control viscosity to reduce runniness in applications. |

Stay Informed and Updated

The field of Woodworking Adhesives is ever-evolving. Regularly check resources such as the Wood Magazine and Woodworking Network for the latest products and techniques. Knowing the advancements in adhesive technology can keep your projects at the cutting edge.

By applying these innovative techniques, you can improve your woodworking bonding processes significantly. The right choice of adhesives combined with proper application methods will lead to successful, long-lasting projects that showcase your craftsmanship.

Conclusion

Selecting the right Woodworking Adhesive can greatly influence the success and durability of your projects. By understanding the various types available—like PVA, epoxy, and polyurethane—you can make informed decisions that will cater to the specific needs of your work. Each adhesive comes with its own set of advantages and potential drawbacks, so weighing those factors is crucial.

Effective application is vital for achieving a strong bond. Tips such as ensuring surfaces are clean, applying the correct amount of adhesive, and allowing adequate drying time can make a significant difference in the finished product. Common pitfalls, such as using the wrong adhesive for the material or neglecting to clamp pieces together, should be avoided to prevent frustration and wasted effort.

Innovative techniques, such as using strategically placed dowels or screws, can enhance bonding and add strength to your projects. Exploring these methods opens up new possibilities for creativity in woodworking.

As you embark on your woodworking journey, remember that using the right adhesive and techniques will not only enhance your projects but also build your confidence as a craftsman. The right choice fosters lasting results, ensuring your hard work stands the test of time. With careful consideration and practice, you’ll find that mastering Woodworking Adhesives can elevate your skills to new heights, leading to more impressive and enduring creations. Happy woodworking!